In the disposable shaving razor industry, building a better razor has been a numbers game. First there was the single-blade, then the double blade, then the triple blade. One company even came out with a seven-blade razor. More blades, the thinking was, the better the shave.

“We refer to it as the blade wars,” says Elizabeth Maul, group insights, innovation and sustainability officer for BIC. A longtime fighter in those wars, BIC produced the first single-piece disposable razor back in 1975. (Blade count: one.) But recently BIC started to reconsider the battle. Maybe, just maybe, more blades was not the solution.

So BIC spent the last five years researching and designing around what could make measurable improvements in the shaving experience. The company surveyed customers, and learned that, yes, they wanted a smoother shave with fewer nicks and cuts—the front line of the blade wars. But they also learned that a big part of what makes a shaving experience unpleasant is the inevitable clog in the blades from all the shaved hair. And when there’s more blades packed into the tiny space of a razor head, there’s more chance for clogging to occur.

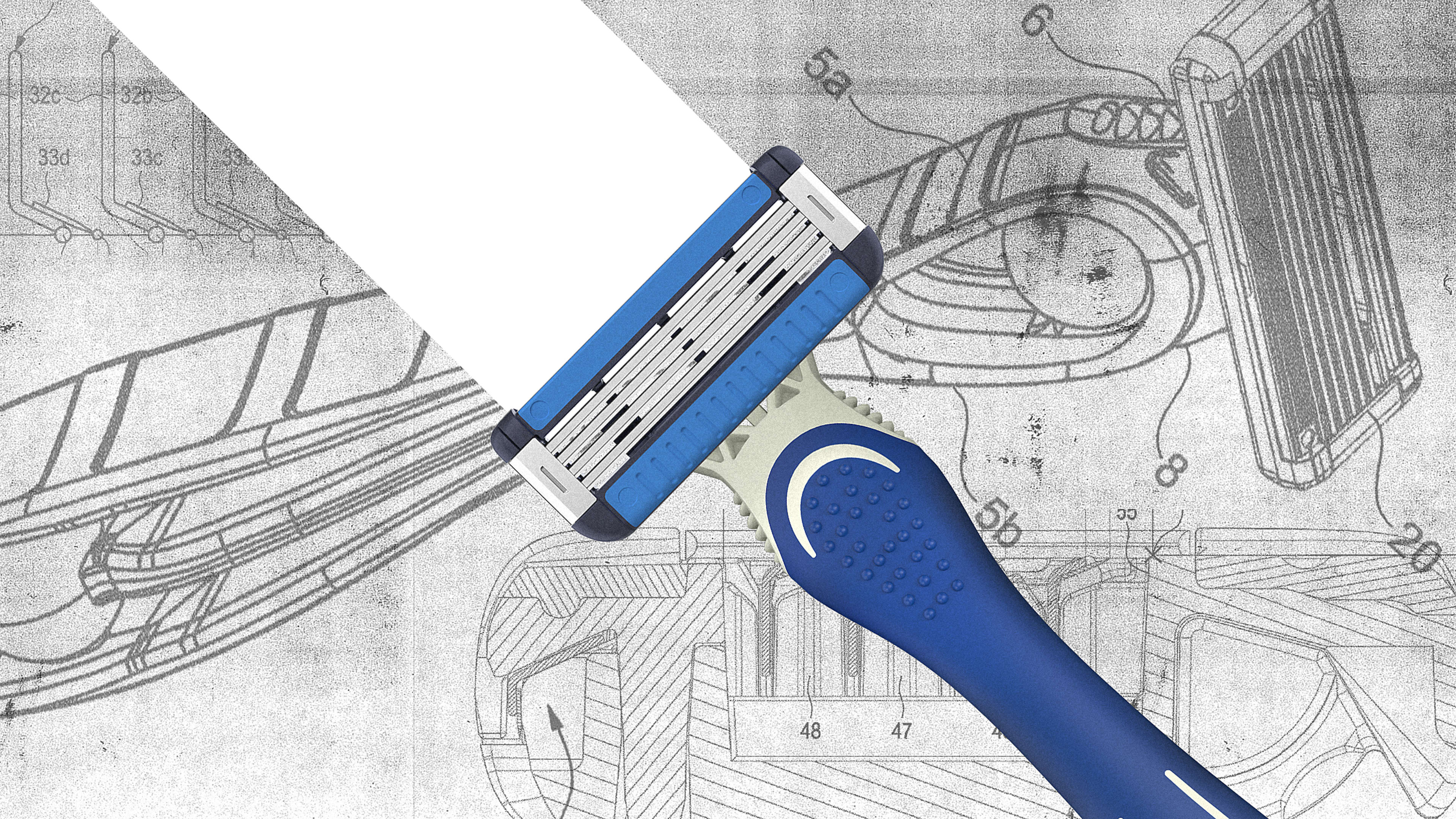

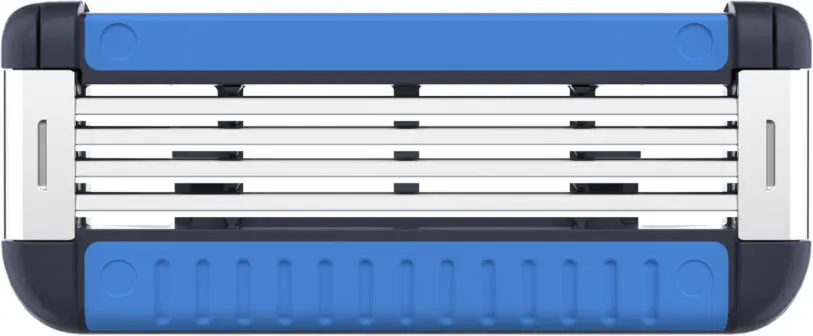

BIC’s solution is the EasyRinse, a razor head with added space in between the blades to reduce clogging and make rinsing faster. Still a valiant blade warrior (blade count: four), the razor head itself has also been redesigned to put more even pressure on the skin, reducing nicks and cuts.

Key to the design’s easier rinse-ability is the way the razor head connects to the handle, which is attached closer to the bottom edge instead of being smack in the middle. Without that attachment architecture in the way, water can flow more easily through the blades, unclogging the head. “This was actually a simple fix that made all the difference in the world, and no one had ever done it before,” Maul says.

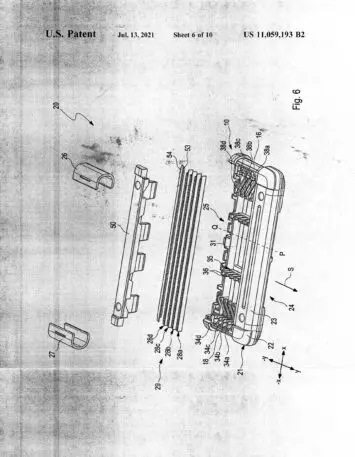

The four blades are positioned to have 30% more inter-blade space, further reducing clogging. And Maul says that because the blades are attached to the underside of the armature of the razor, they’ll draw across the surface of the skin more smoothly. Internal studies show the razors requiring 30% fewer rinses, 60% less rinsing time, and 20% fewer strokes.

The company has filed 21 U.S. patents related to this razor, covering details including the variable increased inter-blade spans, the precise connection of the blade to the support armature, and the method of manufacturing the supports.

“There hadn’t been this level of patents for ages, because with the blade wars, [the focus] was how can we add more,” says Maul. “It was really about more, not different. Here it’s fundamentally different in the way it’s being built.”

Mercifully, the blade wars may soon be over. But a new battlefield of more intricate industrial design is now emerging.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.