For years, the fashion industry has been trying to find a way to turn old clothes into new ones, the way we currently recycle cardboard or aluminum cans. Now, the technology has finally arrived. And if you stop by an H&M store in Stockholm, you can see the process before your eyes.

Pascal Brun, H&M’s head of sustainability, says the point of this particular machine isn’t to recycle garments at an industrial scale. After all, H&M is a $26 billion global company that makes millions of garments a year. The idea is to show customers how fabric recycling works so that they’ll be motivated to bring in their old clothes.

Right now, 87% of the material in clothes ends up incinerated or in a landfill after its final use, according to the Ellen MacArthur Foundation, a leading sustainability nonprofit; the rest tends to be used in things such as rags, insulation materials, and mattress stuffing. Only 1% of the material used to produce clothes is recycled into new clothing. Not only is this environmentally devastating—it also represents a loss of more than $100 billion worth of materials every year. H&M, in particular, is one of the worst offenders of fast fashion—in 2018 it said it had $4.3 billion worth of unsold inventory. The company has made previous efforts to position itself as a sustainability leader but has come under fire for being deliberately vague.

“Several years ago, we realized we needed to invest heavily in fabric recycling, but one major stopgap would be collecting enough discarded clothes to make this work at scale,” says Bang.

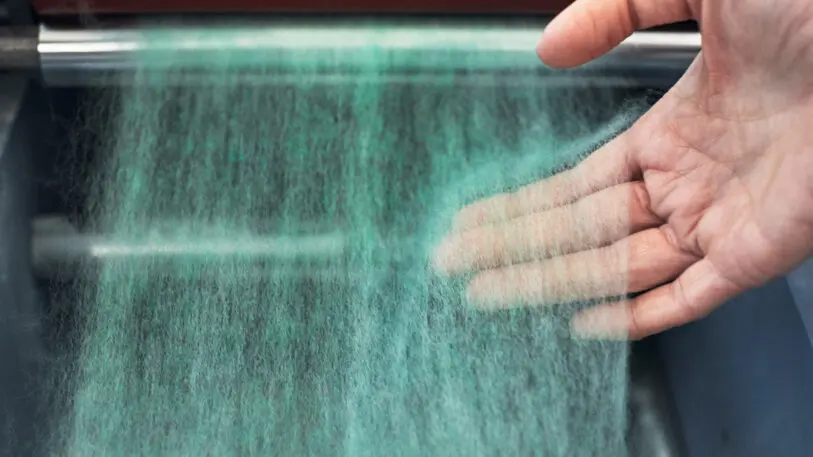

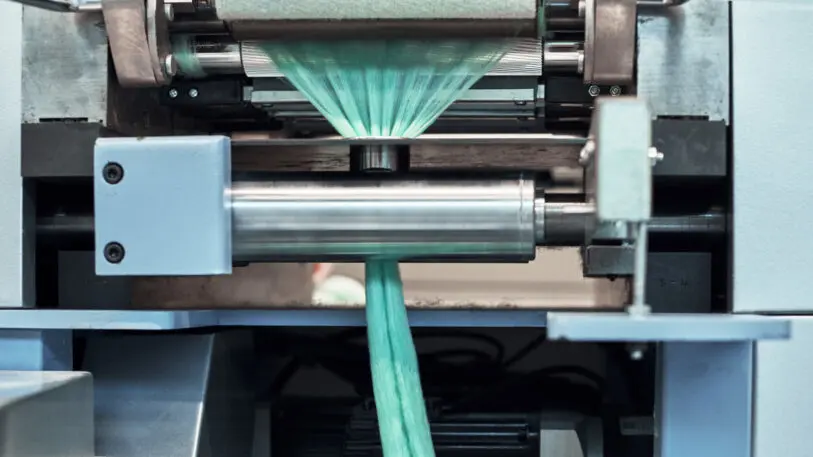

The H&M Foundation has invested in Looop technology, which was developed by the Hong Kong Research Institute of Textiles and Apparel and Novetex Textiles. The system cleans garments and shreds them into fibers, which are then spun into new yarn, which is knitted into new garments. The system doesn’t use any water or chemicals, and the process is designed to have a lower environmental footprint than making clothes from virgin materials. Looop is now beginning to scale up this technology to an industrial scale, and when that happens, H&M hopes to start manufacturing clothing using these recycled fibers.

H&M has already partnered with Infinited Fiber to create garments using these regenerated fibers. They can be transformed into a range of fabrics—for instance, jersey and denim. Alava says that the infrastructure for collecting and sorting through clothes for recycling is still in its early stages and will need to be developed for large scale operations to become feasible.

Ultimately, though, recycling fabrics is just one part of H&M’s broader sustainability strategy. The company’s goal is to become climate positive by 2040, which means cutting more greenhouse gases from the atmosphere than it emits. Fabric recycling is a step toward this goal, but H&M will have to make massive changes to its business model to truly be sustainable. Bang acknowledges that it’s important to reduce the overall number of clothes H&M produces. To this end, the company is looking at creating clothing rentals or a secondhand market for its products. “Sometimes, the most sustainable solution is not to recycle a garment,” Bang says. “You also want to keep that item in circulation for longer, so it gets as much use as possible. Fabric recycling is just one tool in the toolkit.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.