Dairy alternatives—pea milk, almond milk, soy milk, coconut milk, oat milk, and a plethora of alt-cheeses, yogurts, and other products made without any involvement from cows—have become ubiquitous. But few would ever be mistaken for the real thing.

Perfect Day, a startup that uses fermentation to make proteins that are nutritionally identical to those in cow milk, is different: A sample of “ice cream” made with the company’s milk protein, for example, tasted exactly like regular ice cream to me, representing a fundamental shift for the industry. Today, the company announced the closing of a $140 million series C funding round that will help it bring its ingredients to market.

The key to making products that truly taste like dairy, the founders say, is milk protein. “You can take coconut oil and non-lactose sugars and make a frozen dessert,” says Ryan Pandya, CEO and cofounder of Perfect Day. “But if you don’t have milk protein, you’re not really able to hold these things together and have a creamy milk profile and flavor release that’s typical of dairy.” Milk protein plays the role of binding water, fat, and everything else together. Many existing plant-based dairy products have little protein, he says, but even those that do rely on stabilizers and gums and emulsifiers to try to hold the product together, and it doesn’t work well.

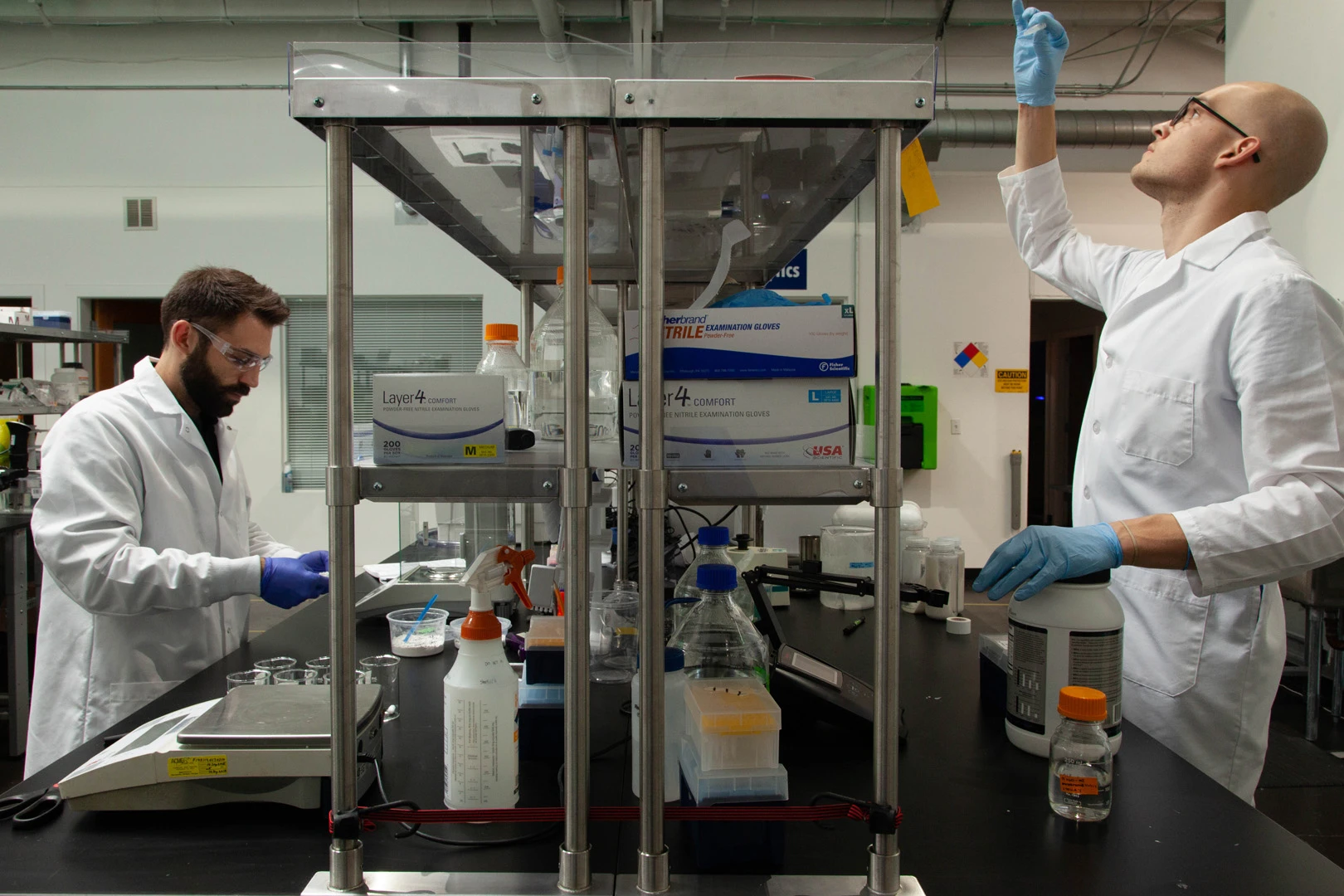

To make milk protein without cows, the company uses microbes programmed to produce the protein, a variation on the same process that is already used by other companies to make vitamins, probiotics, and ingredients like heme, which Impossible Foods uses to help give its plant-based burger the flavor of meat. Perfect Day calls its product “flora-based dairy protein”; the flora are the tiny organisms used to produce it.

Although the company made a test batch of ice cream with the product this summer, which sold out the same day, it doesn’t plan to make products itself. “Every day, every decision, the thought process is, ‘How do we make this scale big enough that everyone in the world can have access to it?'” says Pandya. “I think it’s a very different kind of thought process than saying, ‘How do I build a $10 billion brand?’ That’s not really the goal here. The idea is to make this as impactful and achieve our mission as quickly as possible. And the way to do that is by partnering with brands that are big and small and have much wider reach than we could simply as our own product.”

That means working closely with the dairy industry. Pandya says that even dairy farmer co-ops have expressed interest in partnering on production. “Perfect Day’s goal is to be in collaborative with the industry and not to sort of be adversarial or make things harder,” he says. “We view ourselves as part of the innovation of the dairy industry.”

At the moment, the industry is struggling. Between 1992 and 2018, according to the National Farmers Union, more than 94,000 family dairies went out of business. As milk sales fall, plant-based dairy sales continue to grow, and now make up 13% of the milk category. Some dairies are evolving; at least one historic dairy, Elmhurst, now makes nut milk.

At scale, the company says the product can be as much as 40% cheaper than milk protein from cows. It also avoids tremendous environmental impact. In an early life-cycle analysis that compared a gallon of milk from a cow to a gallon of its own product, the company found that it could eliminate the vast majority of the water and land used on a dairy farm, along with more than 80% of the greenhouse gas emissions.

The new funding will also help the company continue to refine its products, including an animal-free version of milk fat that it recently developed. Plant-based fat also doesn’t work as well in some applications, like butter. And although the company’s protein can be used with plant-based fats like coconut oil, it realized that the demand for coconut oil could cause supply chain issues in the future.

By replicating traditional dairy, the company hopes to accelerate the shift away from the cow-based industry. “We’re creating products that are more compelling for the mainstream,” says Pandya. “It’s one thing to be vegan or only eat lactose-free products . . . but for everyone else who just love dairy, there needs to be a compelling reason to switch to something kinder and greener. Once we’ve developed this and brought it to the world in a big way, we’ll find that it’s much easier for a larger percentage of the population to actually make this switch.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.