Inks, paints, pigments, and dyes have come from the natural world for centuries. During the Renaissance, the gemstone lapis lazuli was ground down to make rich ultramarine blues and cochineal insects were used to make deep red pigments (and still are); minerals like copper and lead were used in green paint; and carbon-derived soot and charcoal were responsible for black ink (and guess what, petrochemicals still are). Pigment was bound together with a binder like linseed oil or egg yolk to make paint.

Chemical innovations in the nineteenth century produced the likes of viridian green, cadmium orange, and chrome yellow. As you might be able to tell from even just this short list, toxicity varied. Letterpress inks followed a similar trajectory, and moved away from the paint-like inks of Gutenberg’s letterpress toward chemical and synthetic inks in the late nineteenth and early twentieth centuries. But now a new innovation in ink is going way back. In fact, it’s made from some of the earliest organisms on earth: algae.

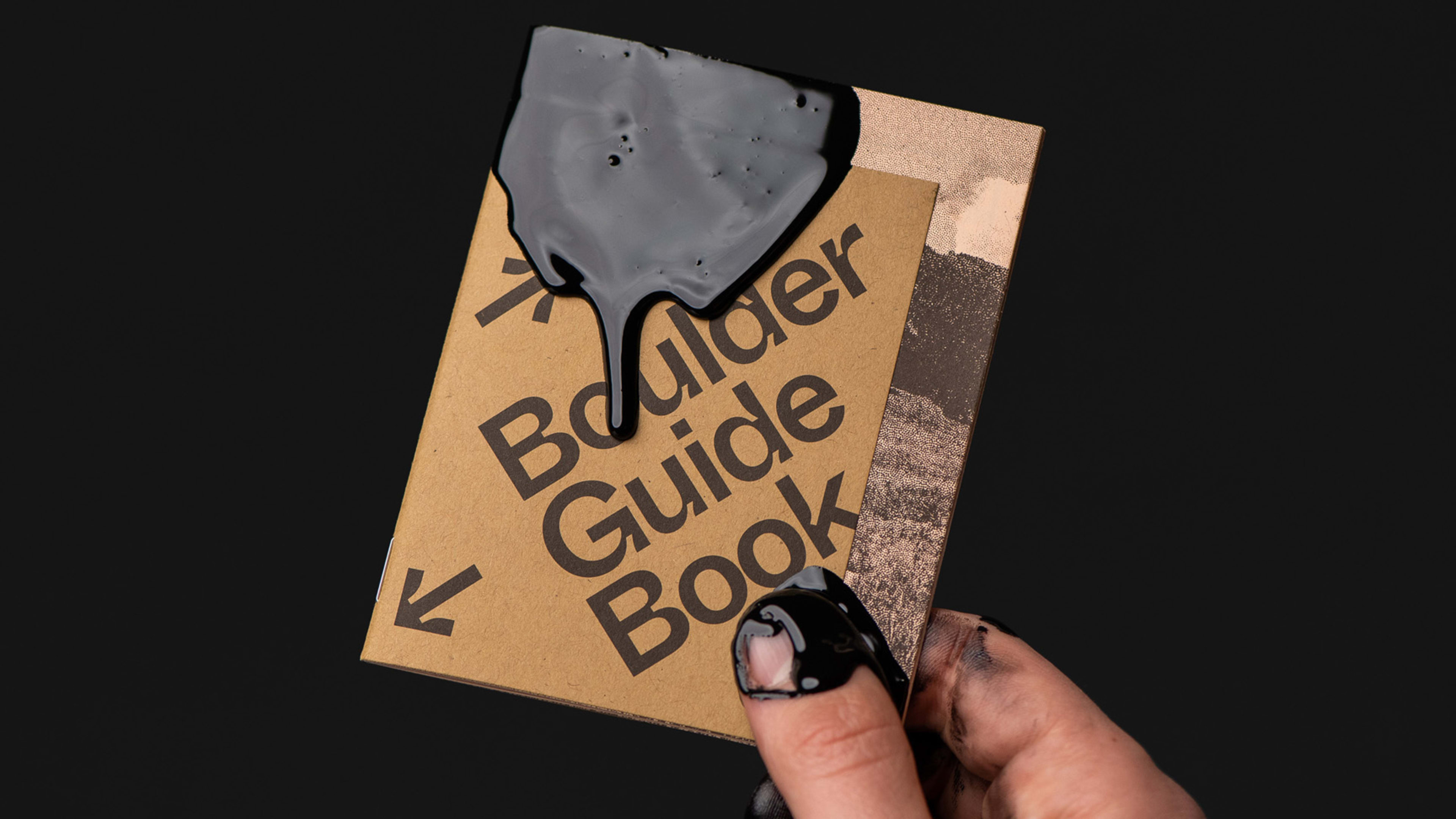

When the company with a mission to “save our home planet”—Patagonia—asked Cast Iron Design to make a printed guide to Boulder, Colorado, the team knew they had an opportunity to “push the sustainability envelope,” according to the Cast Iron Design website.

So the team took several steps to create a booklet that aligned with the values of Patagonia in both look and make. According to the site, the guide is made with uncoated paper stock that has a natural feel reminiscent of the city it’s designed for. The booklet was manufactured carbon-neutral. It uses 100% post consumer waste recycled fibers and was processed chlorine-free. But the agency went another step further and made the ink carbon neutral, too.

Cast Iron Design partnered with Colorado biomaterials company Living Ink to replace the petroleum-based pigments found in traditional black ink with an algae base, creating what they claim to be the “world’s first algae offset ink.”

[Image: Cast Iron Design]

To bring it to life, Living Ink used an extracted byproduct of spirulina algae, grown by Irvine, California-based Earthrise Nutritionals, as the base material to create the renewable, bio-based carbon black ink. That crude pigment is then purified, milled, and formed into a dispersion similar to the typical carbon black. The result is a sustainable alternative to traditional carbon black ink pigment, “which is produced from heavy crude oil, generates a significant carbon footprint, and is listed as a class 2b carcinogen,” says Scott Fulbright, Living Ink’s cofounder, in a statement to Fast Company.

The Cast Iron Design team sees algae as a promising alternative not only because its use could offset the use of nonrenewable resources in print production, but because it could actually be carbon negative due to the fact that it goes through photosynthesis. (As a plant, it consumes carbon dioxide and produces oxygen.)

While Cast Iron Design considers this first use of algae in offset printing as a test case, it expects that this trial run of 8,000 booklets will take algae offset ink closer to commercial viability, calling the potential of the technology “substantial.” Design’s potential to harness earth’s natural resources and decrease our carbon footprint? Seemingly better with every batch. Pass the spirulina.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the final deadline, June 7.

Sign up for Brands That Matter notifications here.