It has been 70 years since modern solar panels were invented, and their fundamental design hasn’t changed all that much. Yes, their efficiency has more than doubled since then, and the price has dropped by 89% since 2010. But recent innovations aside, the majority of solar panels still consist of silicon cells sandwiched between glass and plastic, encased in an aluminum frame, then clamped to an array of rails that are bolted on a roof, or secured with concrete ballasts.

Solar adoption in the U.S. is booming, but how much more power would we be using if we could manufacture panels that are easier to install and lighter to transport? MIT engineers have been working on this very question over the past decade. Their latest answer? Solar cells so light and so flexible that they can be laminated onto almost any material, like the fabric of a disaster relief tent, the sail of a boat, or even “a large carpet that can be unfurled on top of a roof,” says Vladimir Bulović, a professor of electrical engineering at MIT and the co-author of a new paper on the subject.

The thing about the way solar panels are made today is that the actual photovoltaic cells, which are responsible for converting sunlight into electrical energy, are incredibly brittle. Left unprotected, inclement weather will destroy them. As a result, protecting the cells requires tremendous infrastructure, which causes solar panels to weigh two to four pounds per square foot, or about 40 pounds for one average-sized residential solar panel.

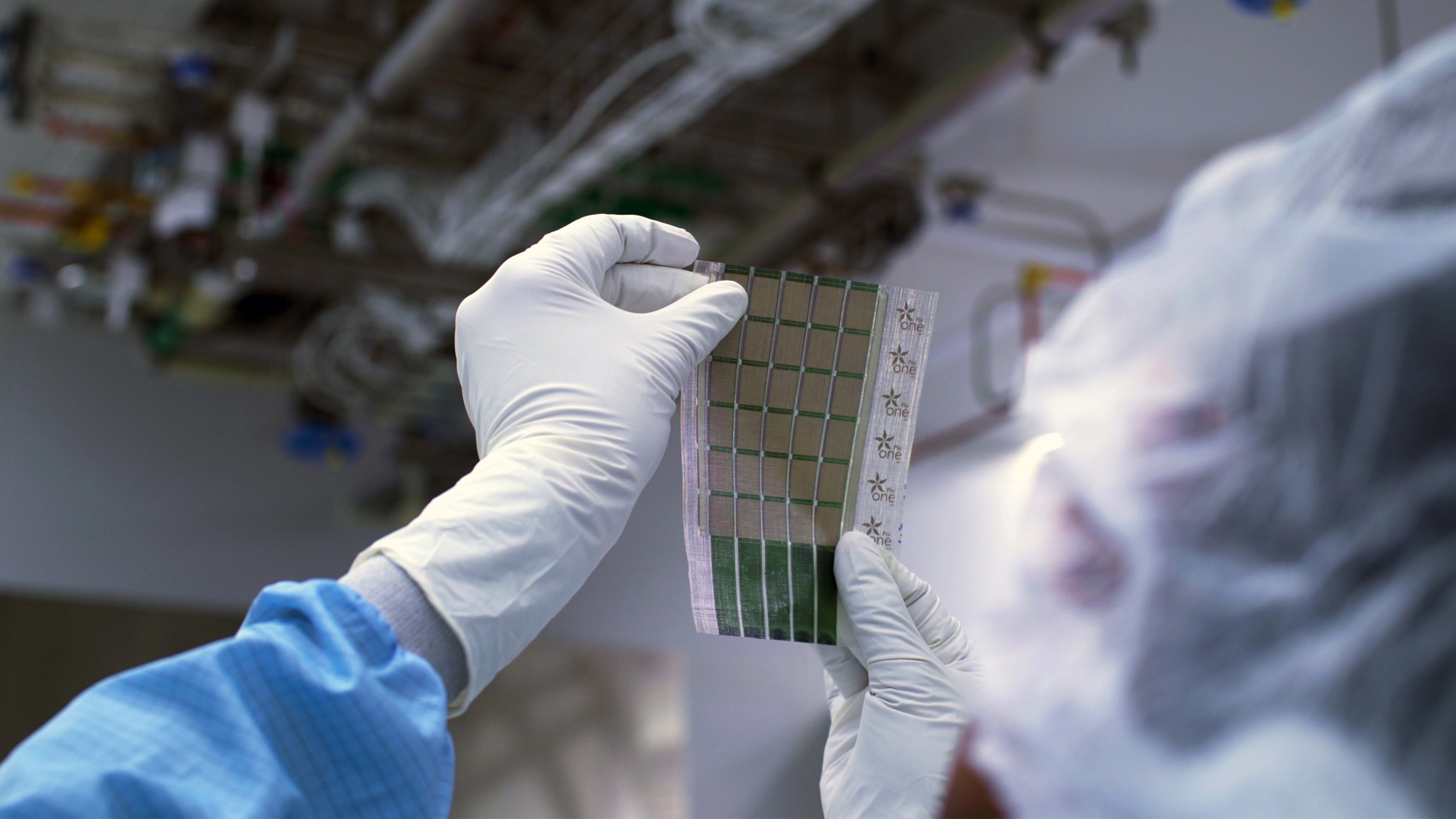

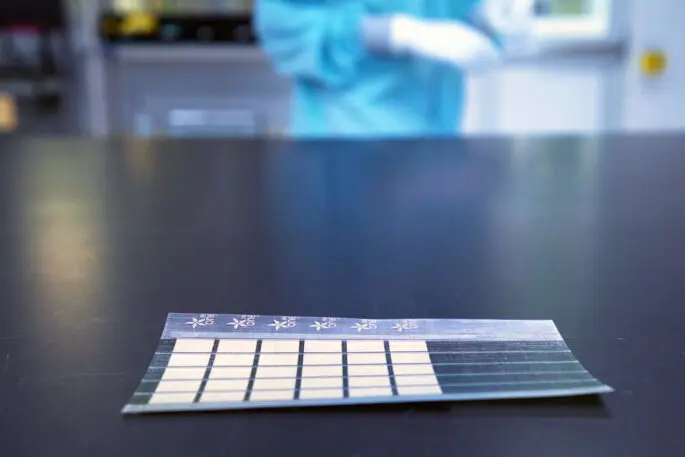

By comparison, MIT’s cells require very little infrastructure. As a result, they are one-hundredth the weight of conventional solar panels. That’s because Bulovic’s team found a way to design cells that are thinner than a human hair. To do this, the engineers used printable electronic inks and followed a technique similar to the way designs are screen printed onto a T-shirt. First, they printed the electrodes on a flat sheet of plastic. Then, they glued the sheet of plastic on a chosen surface, in this case a sturdy fabric called Dyneema. Lastly, they peeled away the fabric, which has picked up the electrodes, leaving a clean sheet of plastic behind. In theory, the process could work without the middle step, but Bulovic explains this would limit the selection of fabrics considering the cells would have to be printed on a perfectly flat surface, which is incredibly rare at this nanoscale.

For this research, the team chose Dyneema for its incredible strength. Bulovic says the fabric’s fibers are so strong that it’s used to make bullet-proof vests and the ropes that were used to pull the stranded, 220,000-pound Ever Given ship from the banks of the Suez Canal last year. Bulovic adds that the technique could work on nearly any surface, from thin plastics to metals to anything that can be laminated. “We have a unique opportunity to rethink what solar technology looks like, how it feels, and how we deploy it,” he says.

The solar cells are not quite as efficient as the more traditional silicone panels. Compared to their traditional counterpart, the cells can generate about half the energy per unit area, but astonishingly, they can generate 18 times more power per kilogram. This means that if a ship were transporting a certain number of pounds worth of solar panels to a disaster relief zone, it could deliver 18 times more power per weight. In the long-run, Bulovic says the team will be able to match the efficiency of silicone panels by switching to another kind of cell known as a perovskite solar cell. But for now, the point isn’t to replace traditional panels. The point is to make solar energy more accessible and portable, so it can be used in scenarios where traditional panels can’t.

And when it’s time to distribute the power on site, heavy panels could be replaced by light and portable objects like laminated tarps with ultra-thin solar cells on top. “My expectation would be that the format of these new cells should allow us to completely rethink how rapidly we can deploy solar cells, and how rapidly we can manufacture solar cells,” he says. “In the long run, we think this can be as rapid as printing a newspaper.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.