Henrik Stiesdal was technically on holiday when the bright-yellow floating steel platform he designed set off on its maiden voyage across the North Sea in late July 2021 with a single wind turbine mounted on top.

The contraption—a hulking 740 feet tall and weighing several thousand tons—represented the culmination of five years of work for Stiesdal and his small team, who had endlessly tested and tinkered with the design so that the turbine and its platform would withstand the harsh conditions at sea.

The wider energy industry was watching the launch, too. While other companies had set up similar projects, none had the cachet of Stiesdal’s. A legendary figure in the renewables industry, the 65-year-old Dane was one of a few pioneers who championed the three-bladed turbine in the late 1970s, paving the way for wind power’s expansion as one of the world’s dominant sources of renewable energy.

“That was a big moment. It was also a little bit scary,” Stiesdal says now. “It’s always like that when you are doing something entirely new.”

A lot was riding on that journey through the North Sea, which came amid a heated race to design the next generation of offshore wind parks that can float in the deep waters found along most countries’ shores. Wind power now comprises up to 7% of global electricity production, and Stiesdal was certain that opening up vast new areas for additional development would be the next big step for the technology, vaulting it into the stratosphere.

Developing his latest floating design had cost around $50 million, a sum financed by a trio of leading energy companies. Stiesdal was hoping to convince them that his platform design would stand out in a crowded field of competitors. Success could mean the chance to license his design to dozens of developers in what is poised to become a multibillion-dollar business. Failure, on the other hand, could mean the godfather of the wind industry might well miss out on its biggest chapter yet.

But the conditions for that fateful launch last July turned out to be less than ideal. A bad radio connection hindered communication with the captain of the towing vessel, while stormy seas constantly threatened to force the ship to take shelter in Norway’s famous fjords. So Stiesdal, a mild-mannered man with a penchant for self-deprecation, spent his holiday glued to his iPad, poring over weather data and refreshing the ship’s location beacon.

“We had to do operations we had only done on paper before,” Stiesdal says. “That was a completely different stress level.”

https://twitter.com/HenrikStiesdal/status/1465950696210116613?s=20&t=4kYIeIGPb8BjkOGB8jyGmA

To date, offshore wind parks have been installed only along a small share of coastlines around the world—mostly in northern Europe and China—and their potential for further growth is limited.

Companies can install only traditional bottom-fixed turbines, which see the mills sitting atop steel pylons driven into the seabed, in shallow waters up to a depth of around 160 feet. But the vast majority of the world’s coastal waters are much deeper—including in large parts of the U.S. and Asia—requiring an alternative approach for the industry to expand in a significant way. Plus, local opposition to turbines that are visible from land has risen sharply in recent years, prompting developers to push farther offshore.

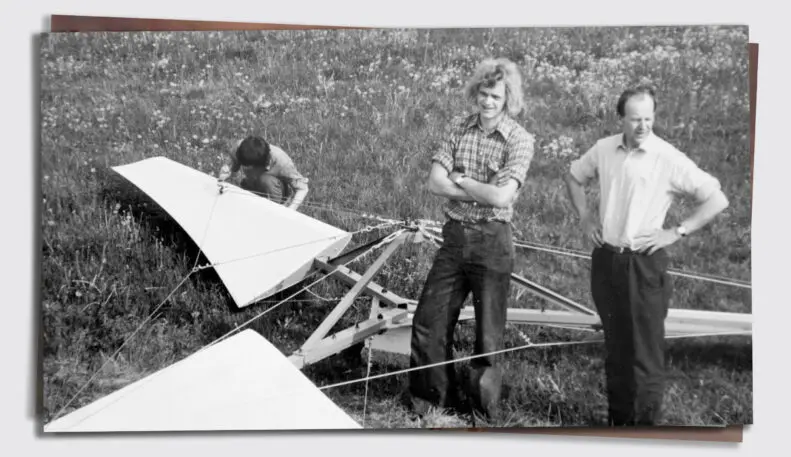

As it happened, a local maker of hydraulic cranes named Vestas had also started experimenting with turbines—the early, ill-fated efforts shaped like a whisk—and the company decided to simply buy the license to Stiesdal’s now ubiquitous design by the time he turned 22.

The intervening decades saw him push the boundaries of renewable energy again and again, designing critical improvements to wind technology—like weatherproofing turbines against lightning strikes and launching the world’s first offshore wind farm in 1991 while working at Bonus Energy, a Danish company later bought by Siemens. Throughout that time, he racked up more than 200 inventions listed in the European Patent Register.

With floating turbines poised to make up a rapidly growing share of that market, a massive opportunity is all but guaranteed for whoever can design a commercially viable solution first. “There’s just no choice,” says Noé Rouxel, an offshore wind expert at global advisory DNV. “Floating wind is really the only way to go.”

Each model requires years of testing and monitoring, and some early efforts did not pan out as planned. Norwegian oil firm Equinor launched the world’s first floating prototype back in 2009, which turned out to be mostly suited to the company’s native fjords. Equinor now has several wind farms in the water testing a newer foundation designed for broader use.

“The number of players in this field grows almost on a daily basis,” Stiesdal admits. “Not everybody will succeed, that’s obvious.”

Stiesdal has support from oil major Royal Dutch Shell, as well as two utilities, all of whom already develop conventional offshore wind farms and put up the roughly $35 million to build and deploy Stiesdal’s floating prototype. (His company, which has also received direct investment from the likes of Denmark’s pension fund, shouldered the remaining $15 million in development costs.)

Stiesdal claims his prototype is the first industrially manufactured foundation deployed to date, which he says was partly achieved by reusing components from conventional offshore wind farms. His design also uses stainless steel pins mounted in plastic bearings to hold the different parts of the platform together, which means it can be more easily assembled in port and serviced at sea.

DNV’s Rouxel says Stiesdal’s design, which can be adapted for various water depths, is indeed innovative. But he points out that other companies aren’t far behind him—and no one, including Stiesdal, has yet proven their designs on a large scale.

Stiesdal’s concept also might not work in locations like California, where there is no existing offshore wind supply chain to draw on. All this means that big developers have so far avoided committing to any one design for their first large-scale projects, preferring to keep playing the field instead.

“They’re trying to get their feet wet with different technologies,” Rouxel says of Shell and others. “They haven’t closed in on any solution yet—and they really don’t want to until the last moment.”

Thomas Brostrøm, who’s in charge of renewables at Shell, says the oil company will trial some other designs in an upcoming three-turbine pilot project in France before deciding on which platform to use in its first commercial-scale floating wind farm in South Korea, which it plans on building toward the end of the decade.

Some countries, including France and the U.K., have started auctioning off rights to develop gigawatts of floating wind farms; Shell and a partner won 5 gigawatts in the U.K.’s first round earlier this year. Several other projects—each capable of supplying power for hundreds of thousands of households—are also on the horizon.

Consensus in the industry is that only a handful of different floating platforms will eventually become widely used, out of some 50 designs currently in development. Still, Stiesdal’s background and experience have already shown him to be a promising contender, according to Brostrøm.

“Henrik is a very smart and entrepreneurial guy, but he’s also worked for some big companies,” the Shell executive says. “He’s coming in with the right mindset in terms of what it would take to be a winner here.”

Although the success of the launch has put him in a pole position, Stiesdal is surprisingly sanguine about the prospect of other companies’ designs beating out his own. He appears more occupied with the larger goal of making floating wind cheap enough for widespread adoption.

He also points out that some of the solutions he discovered while designing his prototype—including new cabling and mooring technologies—could equally benefit his competitors. If other companies end up cornering the market, he figures he’ll still have accomplished his mission.

“We are not a ‘make little Henrik successful as a businessman’ company—that’s not the issue,” he says. “I really think that what we do here matters.”

Speaking to Stiesdal, it’s clear that what started as a simple distraction has turned into somewhat of an obsession with devising climate solutions—one that extends beyond wind power. Stiesdal’s company, which he started in 2016, is working on a slew of other promising technologies, from storing heat in crushed rocks to making carbon-negative fuel.

After retiring from Siemens, Stiesdal had initially planned to spend more time with his family; he says he was also growing tired of the responsibility that comes with managing thousands of people. An engineer at heart, he’s more comfortable at the drawing board than in the manager’s chair. Still, he soon felt drawn back to a position where he could make a difference.

“The company that I run now, its number-one motivation is climate change,” he says. “That looms very large. I could retire now, but I feel an obligation [to keep going].”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.