Trains may be an old technology, but they are still remarkable machines—operating with roughly four times the energy efficiency of semitrucks driving on a highway.

However, over the past several decades, railways have been working against themselves. To compete with semis, they’ve ceded shorter deliveries. Instead, railways have doubled down on long-haul shipments of 1,000 miles or more. And to maximize efficiency on long routes, train companies have simply kept making trains longer . . . and longer. Today, it’s relatively common for trains to be nearly 3 miles long.

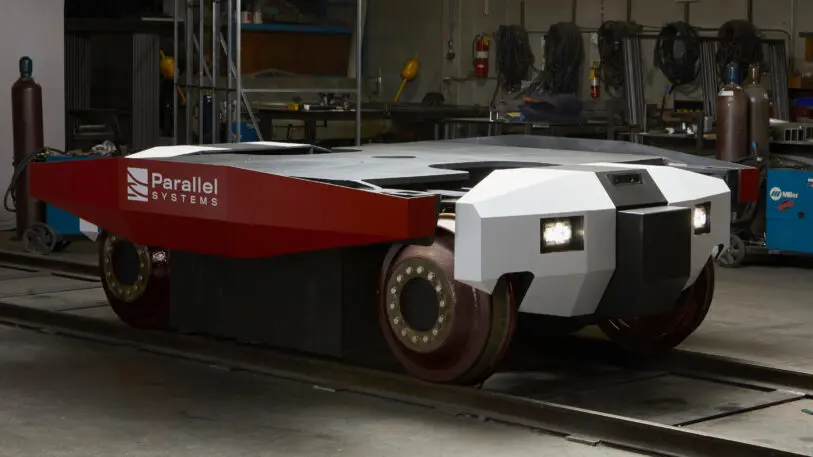

Three years later, with $50 million of Series A funding in hand, he’s sharing his solution. Now the CEO of Parallel Systems, Soule—alongside two cofounders who both led major engineering initiatives at SpaceX—is transforming individual freight train cars into autonomous electric vehicles.

The company’s potential impact is in its ability to redesign the way freight is transported, moving shipments that would have been delivered by truck to a more efficient train. Understanding that impact requires dipping your toe into the 143,000 miles of U.S. railway.

[Image: courtesy Parallel Systems]

How autonomous rail cars could solve a network problem

Dean Wise is the former vice president of network strategy at BNSF Railway (aka the Burlington Northern Santa Fe Corp., one of the largest railway companies in North America). He’s also one of several established industry advisers who Parallel Systems has brought in to help navigate the relatively closed industry of freight transport.

“You actually are not going to get into this game unless the railroads themselves are going to invite you in,” Wise explains. “The rail industry in North America is basically privately held and privately funded . . . and they can say, ‘We don’t like this [idea].'”

Parallel Systems plans to make money by providing its technology to the railroads, rather than competing with them. Meanwhile, railroads make money by charging clients to move their goods (and to break your heart, one of their most popular cash cows is actually coal). In the U.S. and across North America, five regional companies operate the vast majority of railways—and you might recognize them by their distinctive train engines. Union Pacific is the largest, with routes from the Midwest to the West. BNSF has a similar footprint, but reaches north where UP reaches south. Then you have CSX and Norfolk Southern from the Midwest out East. And pushing north? That’s the territory of Canadian National.

[Image: courtesy Parallel Systems]Wise calls this arrangement “co-op-etition.” The same track standard is shared across North America, meaning this network is completely interoperable for all trains on the continent. However, because the network is split among companies, they often have to work together, handing off cargo from one to another for it to reach its final destination (and as a further complication, freight lines share the same track with passenger lines).

While long trains are profitable for the train companies, they’re not terribly efficient for anyone else. A long train is full of goods that need to be delivered to all sorts of different places once they reach a depot—that’s when those goods are handed off to semitrucks. Not to mention that parking a 3-mile-long train vastly limits where it can go. Furthermore, train cars are often parked for days while they wait for other cars to be loaded and unloaded so that they can move, as this giant caterpillar, to their next destination.

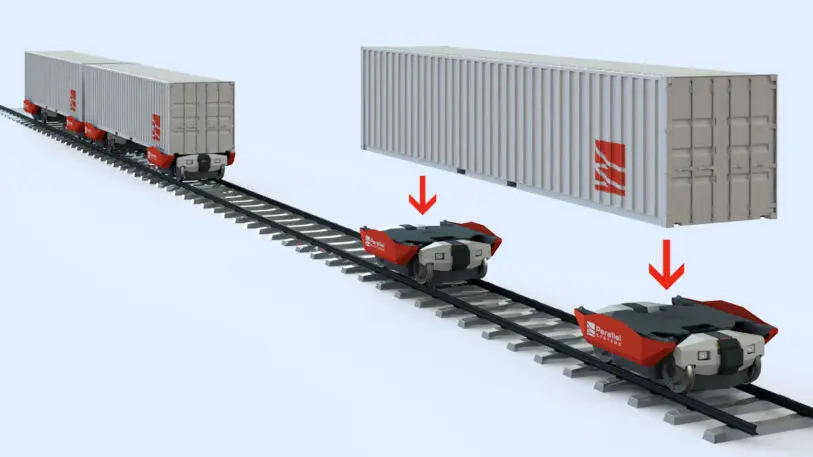

Soule estimates the longest Parallel Systems train might run a half-mile long. But with shorter lengths, train yards themselves can be re-architected to have smaller footprints and fit more places in our infrastructure. Parallel’s platoons can also split themselves in half if blocking an intersection for too long. Because the train cars don’t even couple together (instead, they just push themselves bumper to bumper), it’s easy for them to break rank and let road vehicles pass through their middle.

[Image: courtesy Parallel Systems]Parallel’s trains might cruise down the standard, major railways. But as the platoon approaches its destination, the rail cars could break off from one another onto short-haul tracks. Think of short-haul tracks as the last mile of train delivery. These lines, which run less than 500 miles in length, were mostly abandoned by major players years ago because they didn’t fit the train’s business model. Yet short hauls connect major railways, and they can drive right into a city or even a factory. These use cases might not make sense for a 3-mile-long train, but they might make a whole lot of sense for a three-car train.

“We can do unique things like take a container from a port to a warehouse . . . and you never have to put it on a truck,” Soule says. “And because you don’t have to put it on a truck, you can load more weight.” Parallel Systems cars can carry 128,000 pounds, or 2.8 times more than a semitruck. They also recharge in an hour: Without being plugged in or pulled off the track, the wheels can be recharged to drive another 500 miles.

Autonomous trains are easier to build than autonomous cars

Perhaps self-driving, environment-saving trains that squeeze into our existing railway infrastructure sound too good to be true. Indeed, anyone following railroads knows that short-haul lines have been proposed as a solution to the industry’s woes for years. But Soule points out that compared to building autonomous electric vehicles for highways, building and managing autonomous electric trains is far simpler. Because rails are simpler. Trains stay on a track without a steering wheel. They also don’t need to worry about responding to random traffic. Unlike roads, where pretty much anyone can drive anywhere at any time, railways are tightly controlled and scheduled. Truthfully, some passenger trains have driven themselves since the 1960s. Parallel Systems is simply pushing that autonomy to the individual car level.

The technology isn’t ready for market yet. Parallel Systems has been testing a prototype since November 2020 in California. The company is currently finishing up its second-generation prototype, which it plans to begin testing this year. Until that testing is done, the company is declining to forecast its commercial launch. Though don’t be surprised to see more pilot testing, done in conjunction with railway lines, first. That said, if Parallel Systems can move fast enough, perhaps it can get ahead of the electric semitruck revolution. Tesla recently delayed the availability of its electric semi, while California has targeted 2045 for its zero-emission truck mandate.

“There’s a lot of talk about making trucks autonomous, and a lot of talk about electric trucks. And many railroads are wondering what their future [is] going to look like when those are realities,” Soule says. “We think trucks are going to stay, but what we’re doing is trying to shift the balance.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.