The building you live in, the bridges you cross, and the sidewalks you traverse could one day store electricity.

New research from Chalmers University of Technology in Sweden has shown that, with a minor tweak, the concrete used to build many of the world’s buildings and infrastructure projects can be turned into a rechargeable battery.

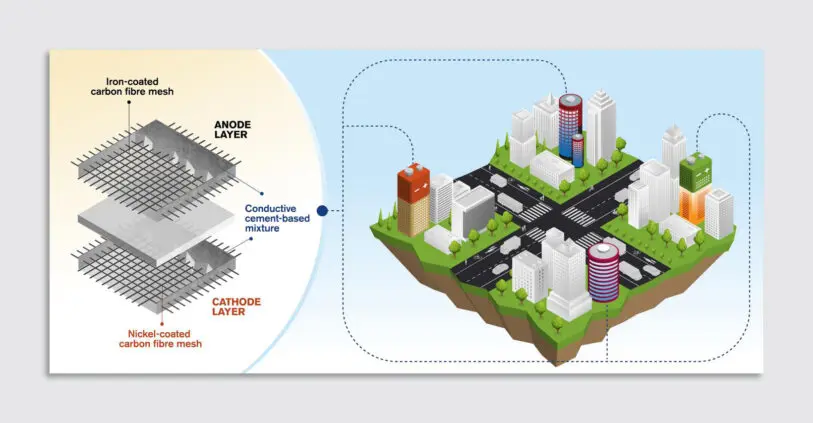

By embedding a typical concrete mix with short carbon fibers, an iron-coated mesh of carbon fiber, and another mesh coated in nickel, the concrete can be made to conduct and store small amounts of electricity. Incorporated at the scale of an apartment building, bridge, or citywide sidewalk network, the energy storage capacity could add up to provide a modest but potentially renewable source of electricity.

Developed by Luping Tang, a professor in the department of architecture and civil engineering at Chalmers University, and Emma Zhang, now a senior development scientist at the engineering and technology company Delta of Sweden, the rechargeable concrete battery is a tangible step toward turning the world’s most used building material—and one of its most environmentally costly—to store much-needed electricity. Coupled with solar panels to generate the electricity, concrete batteries could be a way to chip away at the environmental impact of a material that seems likely to remain a key part of the way the world builds.

An entire building’s worth of concrete to power a light bulb may not seem so impressive, but Zhang says to think beyond that single building to all the concrete structures around the world. “If we take the annual quantity of concrete, it’s about 9 million tons of concrete produced per year,” she says. “If we used all the concrete produced per year to produce concrete batteries, about 3 billion kilowatt-hours of energy can be stored.” That’s roughly the equivalent of the total amount of energy sold to end-use customers in the United States last year. Though a more environmentally sustainable approach would be to stop using concrete altogether, the material’s utility is hard to ignore. If concrete is going to continue to be used, there’s an argument to be made that it should be doing more than just holding up bridges and apartment buildings by storing some of the energy the built world needs.

Turning concrete into a battery might sound like an impossible concept, but the technology behind the idea actually dates back to the early 20th century, when nickel and iron batteries were being developed as an alternative to heavy lead-acid batteries. Thomas Edison used the same approach to build a battery using nickel and iron as a potential solution for powering early automobiles. Though the battery could be recharged quickly, its large size and cost made it less practical than the internal combustion engine.

Updated for modern times and with the relatively new material carbon fiber, Tang and Zhang’s experiment shows that the bulky size of nickel-iron batteries can hide within the buildings and infrastructures built by concrete. Zhang says integrating these materials into concrete mixes wouldn’t even need to be very difficult. “It’s just adding one extra component,” she says.

But before that can happen at a large scale, Zhang says the concept needs to be further developed, and the electricity storage capacity of concrete increased. She believes this is possible, and is hoping other researchers will begin making their own versions of the concrete battery.

“There’s definitely some room for improvement,” she says. “This is the dream of this type of invention. If more people are working on it, of course the time is going to be shortened.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.