The consumer electronics industry has started to make long-overdue changes to the way our technology products are designed, manufactured, shipped, and recycled. But despite commitments to recycling and carbon neutrality, the UN has predicted that e-waste is still set to increase by around 40% before 2030.

The existing linear system, in which our products are developed, sold, and repaired (or not), is helping to fuel this increase. Companies continue to make new generations of products to take advantage of advancements in technology and performance, but also to get people to buy more stuff. As designers and business leaders, we create orphaned products—bringing them into the world with care but giving little thought for their end of life as we move onto birthing the next generation of products to replace them.

We need to start thinking more radically about how we develop new products, and also the supply chains to enable a more circular system that reduces e-waste, beyond the gains from more—and better—recycling.

But is it even possible to create technology products in a truly closed-loop system where we consider reuse, refurbishment, and remanufacturing before recycling? The very nature of cutting-edge product development means core technologies and architectures are still evolving, so that the longer they last the less competitive they become.

So should we simply focus on increasing the efficiency and scale of material recovery from our e-waste as Apple is doing? Perhaps for emerging technology products, like folding screens, AR glasses, and VR headsets that are yet to fully develop. But we are at a point with many of our technology products where their form factors have matured. For everything from laptops, computers, smartphones, and smart watches to home hubs, TVs, and speakers, their product archetypes have stabilized, as the rate of change from one iteration to the next slows. There is now an opportunity to start planning for the design of our next generation of products—not as orphaned new products but ones that are reborn and remanufactured from previous generations.

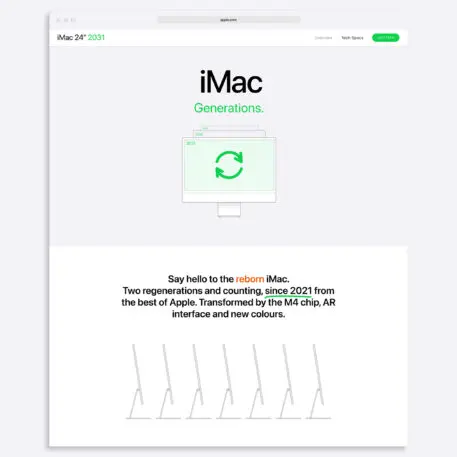

Apple recently established a goal to make every one of its products carbon neutral by 2030 and to incorporate more recycled materials into each of them. This will fast become table stakes in the consumer electronics industry as all companies look to optimize and improve their existing linear systems. But I’d like to think we can stop thinking about our products as a never-ending stream of new generations and think about more transgenerational products—products that can be refurbished and remanufactured time and time again in a truly circular system.

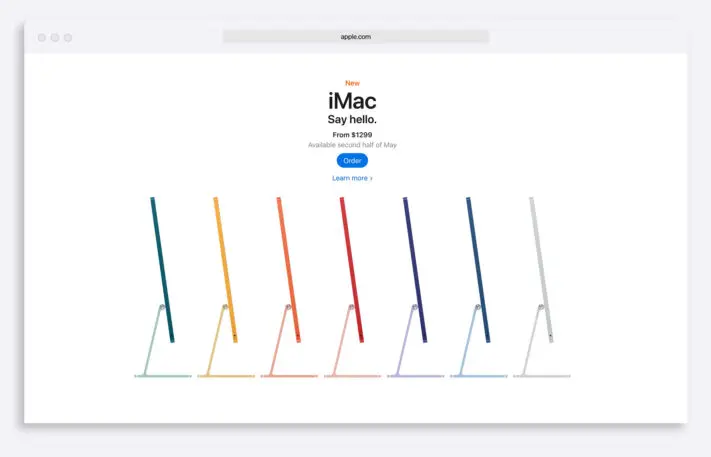

Let’s imagine this 2021 iMac in 2026 when it has inevitably begun to reach the end of its competitive life. Apple could welcome back these products at scale—not for destructive disassembly for material recovery but for remanufacture. It could refinish and reuse major components like the aluminum stand, enclosure, and glass of the screen rather than recycling these back to raw materials. It could update key performance components (e.g., processors and memory chips) to take advantage of technological advancements. It might even look at new manufacturing techniques to modify and improve existing components.

Let’s imagine this keeps happening. It’s 2031 and the iMac has been remanufactured for a second time. Reborn again as the next version of “iMac Generations”: three generations in the making since 2021, regenerated from the best of Apple’s old products, updated with new colors, and upgraded with its latest technologies.

But while we rightly focus on building the capability for recycling at scale, as designers and business leaders we need to think about what we can do beyond recycling. It’s not simply about redesigning our products for repair and recycling. We need to think at a systemic level about the way we conceive our products, the supply chains needed and the manufacturing systems and production methods we use—as well as looking at new business models to support this transition to a truly circular economy.

If we use more imagination now to rethink how we have always done things we have a chance to not only reduce the amount of e-waste and associated emissions but perhaps unlock new value and opportunities for business, consumers, and the planet.

Matthew Cockerill is an independent strategic design consultant dedicated to bringing imagination and vision to the development of future digital products and connected hardware. Through design-led special projects, he uncovers brands’ near-future product opportunities, with the aim of inspiring and accelerating today’s product development and strategic decision-making.

Cockerill has solved complex and ambiguous design challenges for some of the world’s best brands, agencies, and ambitious scale-ups, from designing the world’s first ethical and modular smartphone for Fairphone to crafting innovative TV experiences for Samsung, exploring the future of augmented reality in the home for HTC, and even reinventing the funeral experience for a visionary billionaire in collaboration with starchitect Bjarke Ingels.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.