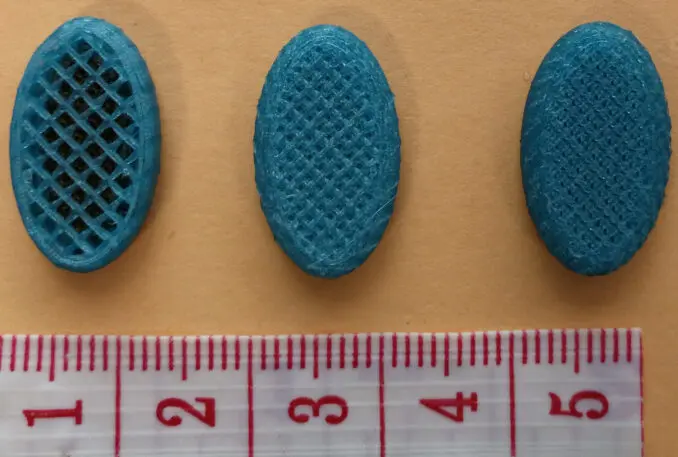

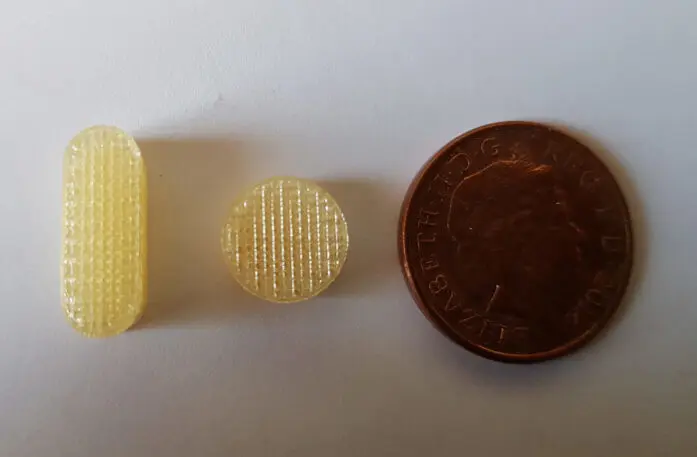

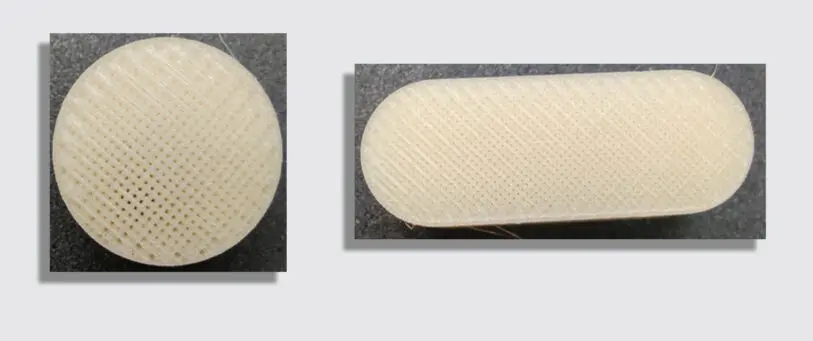

The objects are almost beautiful. The surfaces appear faceted and woven, catching the light like ornate jewelry. But they are not jewelry. They are pills, and possibly the most high-tech pills ever designed, in fact. These tablets are artisanal, tuned for just one person, to release a small medicine cabinet of different drugs at the right time.

Developed by researchers at the University of East Anglia (UEA), these pills are produced by a breakthrough in 3D printing. Today, that printing is done in a lab. Tomorrow, scientists suggest, the work might be done by a pharmacist, hospital, or almost any entity other than separate pharmaceutical companies, each of which currently churns out millions of doses of the same drugs in one-size-fits-all pill formats.

“If patients can take a pill once a day, it’s much easier for them to cope,” says Sheng Qi, a reader in pharmaceutics at the University of East Anglia, who led the research. Indeed, the mental weight of taking many medications a day can be overwhelming to the point where people stop taking their medications at all.

As Qi explains, research in 3D-printed medicine has been booming for the last five years in hopes of solving this. Both academic institutions and private companies are investigating how pills can be produced differently. Traditional pills are made from powdered medicines, smashed together under high pressure to stabilize into a pill. But 3D printing could stack up medicines layer by layer, specially shaping and mixing each layer, so that one drug could release quickly while another releases slowly. The pills are the same size as standard pills.

The new research from UEA pushes printed pills much further. Instead of relying on this indigestible plastic, the entire pill is printed out of finely powdered drugs (which are stabilized, like many pills you take, by a polymer that your body can digest). The 3D printer extrudes medicines layer by layer to build several strata of medications in a single pill.

Because it’s 3D-printed rather than pressed, the pill can be developed in any shape. “We were trying to use the design of the geometry—the porosity—to see if we could simply use design to regulate the rate [of absorption],” says Qi. Basically, if drugs were printed into a spongier structure with more holes, they’d have more surface area open to gastric juices in your stomach, which would break them down faster. If they were printed into more solid structures with fewer pores, they would take longer to dissolve.

Where things get more exciting is that these microstructures can be mixed and matched within a pill. You could have alternating layers of different drugs that dissolve at different rates.

“It’s definitely doable,” says Qi. In unreleased research, she says her lab has already demonstrated that multiple drugs could be released successfully using the architecture of the pill alone.

So what’s next? In the U.S., the FDA is working with the National Institute of Standards and Technology to create guidelines for 3D pill printing, along with other new technologies such as AI in pharmaceuticals. Meanwhile, researchers such as Qi are trying to talk to everyone involved in the pharmaceutical supply chain—including doctors, patients, and pharmacists—to ensure that printed pills can be a viable approach to healthcare.

“We’re trying to get the pharmaceutical industry on board,” says Qi. “Their role will be completely changed. They won’t be the main manufacturer of all this large-batch, one-size-fits-all tablets.” Instead, big pharma would more or less sell a new type of 3D printing filament, a single ingredient for your larger prescription. Whether or not pharmaceutical companies will choose to cede significant parts of their supply chain remains unclear. Besides, no matter how quickly one of these pills can be printed—and the pills currently take about a minute apiece—the process won’t be nearly as fast as traditional pill-making methods, which can press together pills instantaneously on an assembly line. So the method will not replace most over-the-counter pills any time soon, if at all.

Still, this remarkable research could make adhering to complicated drug plans easier than ever, which is the technology’s biggest promise. Yet while ease of use is important in medicine, it’s important we don’t lose sight of the other big reasons patients report not taking their medicine on schedule: high drug costs, and sometimes not feeling like these drugs even work.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.