The call came at 3:30 a.m. “Does your stuff work on COVID?”

Giancarlo Beevis sighed. He had been pulling his hair out trying to lock down a specialty lab that could test his antiviral fabric treatment’s ability to deactivate the SARS-CoV-2 virus. “We’d searched everywhere for anyone who could test for COVID, specifically,” said Beevis, who is the CEO of the Canadian biotech firm Intelligent Fabric Technologies North America (IFTNA). “We weren’t interested in testing it against the human coronavirus, which our competitors were doing, because to us it didn’t have value. We wanted to deal with the pandemic.”

The voice on the phone belonged to longtime client Youngdo Kim, CEO of Okyung International, a Korean textile manufacturer. Turns out, he’d gone to university with a professor who went on to run a biosafety level 3 lab. “Why don’t I reach out to them and see if they can do it?” he said.

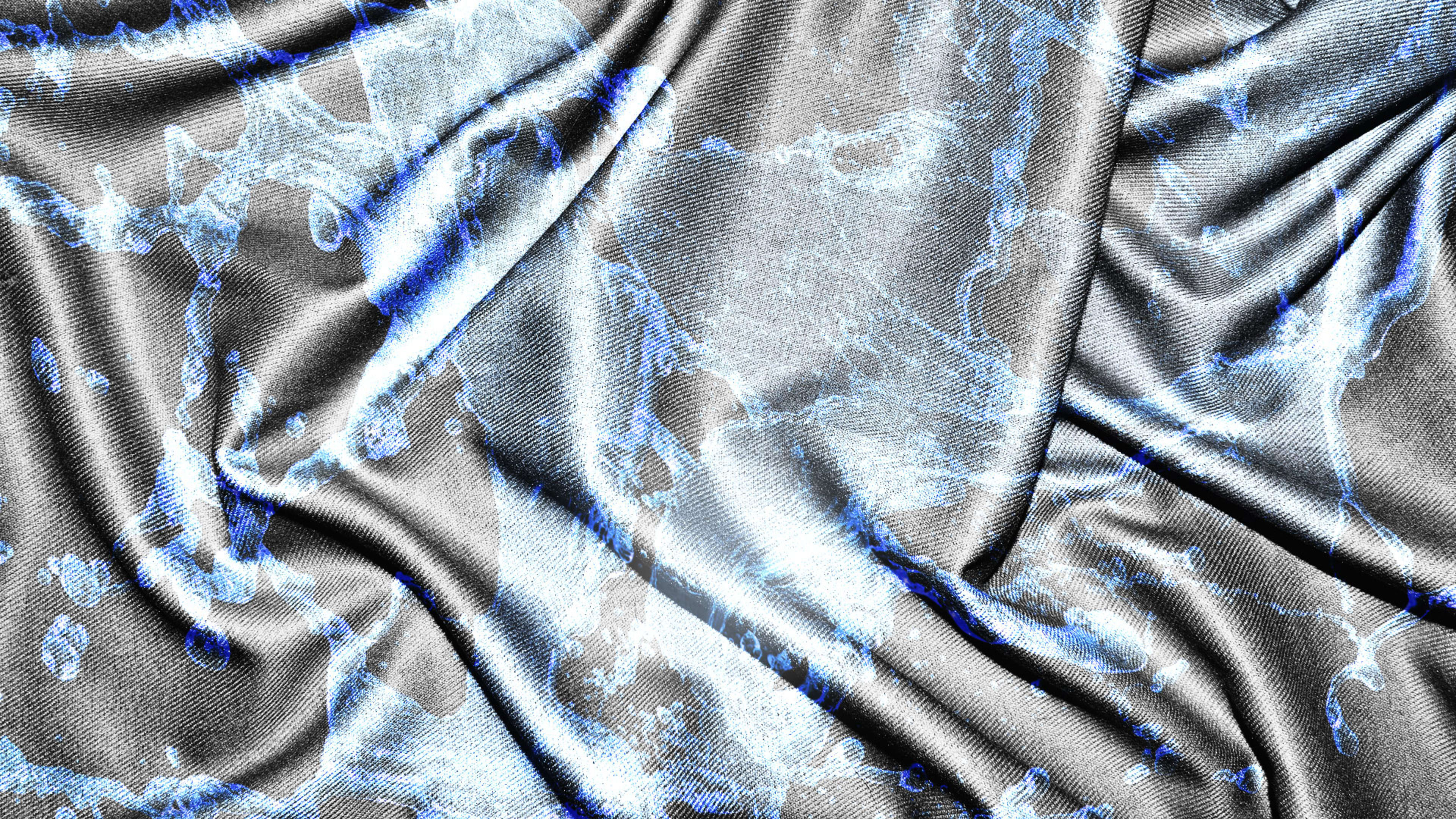

On May 11, Beevis received the lab results proving that his company’s proprietary antiviral chemical—PROTX2 AV (pronounced pro-tex)—destroyed 99.9% of COVID-19 within 10 minutes, with residual killing power for 24 hours. The chemical penetrates the virus’s outer shell and destroys its replication process, and it can be applied during the textile finishing process without requiring additional machinery or steps. An internationally accredited, independent laboratory in Asia—whose name and country Beevis wouldn’t disclose—conducted the tests under American Association of Textile Chemists standards, making it the first antimicrobial textile chemical to be proven, via U.S. codes, to deactivate the SARS-CoV-2 virus.

A scientific and marketing edge

Passing this test, coupled with permission from the Environmental Protection Agency (EPA), will give brands using PROTX2 AV-treated textiles a scientific and marketing edge over products that have only been proven to destroy other types of coronaviruses. The EPA will decide whether the company can claim its product kills COVID in its marketing.

Here’s the difference: Many antimicrobial textile companies cite protection against “coronavirus” in larger letters on their websites, list the non-COVID-19 viruses they do kill in fine print, and present their products against the COVID-19 pandemic backdrop—which uninformed consumers might interpret as protection against COVID-19. But their products may not necessarily work against SARS-CoV-2. There are several kinds of coronaviruses that can affect humans, but only one that causes COVID-19. And although SARS-CoV-2 is a type of coronavirus, viruses don’t react the same way to the same chemicals.

This qualifier also has significant market implications, as loosening restrictions threaten a COVID-19 resurgence. The U.S. accounts for 1.6 million of the world’s 5.5 million cases. Analysts anticipate the global surgical apparel market to reach nearly $19 billion by 2025 and the antimicrobial textile market to surpass $20.5 billion by 2026.

The surge in interest has IFTNA readying a PROTX2 AV-treated laundry additive for home laundering for fall. It’s also starting to produce its own personal protective equipment (PPE) and will launch a lifestyle travel brand called Underit later this year or early next. The PPE and a portion of the Underit line will be treated with the antiviral chemical.

“The antimicrobial textile market is going to be one of the rare markets that is not only having a short-term bounce from the COVID pandemic, but will experience long-term growth,” says Scott Pantel, CEO of Life Science Intelligence, an independent medical technology analysis firm. “Companies like Google, Amazon, and Microsoft are all coming into the healthcare space, and consumer demand for antimicrobial material is going to be massive. If these guys are really the first to successfully test against COVID, they’re going to be huge winners.”

Missed opportunities

If so, it will be a hard-won victory. The firm, a subsidiary of the publicly-traded iFabric Corp, has been creating antibacterial chemical treatments for textile firms serving the medical, athletic, military, hospitality, bedding, and consumer and corporate apparel industries for 12 years. In 2012, IFTNA developed its antiviral version, which garnered little interest pre-COVID.

“No one wanted it,” Beevis says. “The big deal in healthcare environments is bacteria. Their biggest costs involve bacterial infections that make people stay in the hospital longer, cause complications, or create readmittance. Viruses, like SARS or the flu, come and go. But it’s not the main concern in a healthcare facility.”

Giancarlo BeevisOne of the companies docked in Fort Lauderdale for weeks with outbreaks of COVID was the exact company that could have used this technology in 2012.”

That same year, Beevis had unsuccessfully tried to introduce PROTX2 AV to the cruise line industry to control norovirus outbreaks that had been traced to reusable polyester napkins. “We got blocked out by a massive cleaning company,” says Beevis. Discussions ended in a stalemate. The cruise company wanted to add a PROTX2 AV treatment to washes instead of purchasing a new inventory of pre-treated napkins and linens. Its cleaning company wanted to know the kinds of chemicals being used. And IFTNA wasn’t about to release the proprietary ingredients and risk intellectual property theft.

“These were much larger companies than we were,” says Beevis. “They didn’t care enough to make it work, so it stayed on the shelf. Ironically, one of the companies docked in Fort Lauderdale for weeks with outbreaks of COVID was the exact company that could have used this technology in 2012.” Beevis declined to name the cruise line.

What’s next

Beevis is now awaiting regulatory approval. IFTNA is in conversation with the EPA to fast-track its application, under an emergency-use provision, to allow manufacturing partners using PROTX2 AV to legally claim their textiles have been proven to kill COVID-19. It’s also talking to the Federal Drug Administration about approving specific PROTX2 AV-treated devices.

Eventual antiviral apparel should be used to enhance—not replace—other safety protocols, such as handwashing, social distancing, and wearing masks. “As people start to go back to work and we try to restart our economy, they want to feel protected,” says Beevis. “If we can give them another tool to help them, it’s a win.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.