In one worst-case scenario, as many as 960,000 patients with COVID-19 in the U.S. might need to use ventilators, the life-saving hospital equipment that helps patients breathe when they can’t on their own. But there are only around 160,000 ventilators in the country, according to an analysis from the Johns Hopkins Center for Health Security. As manufacturers like General Motors and Ford pivot to making ventilators, a California company called Bloom Energy is taking another approach—refurbishing some of the thousands of ventilators that currently sit in storage because they’ve reached their end-of-service life.

Bloom Energy, a fuel cell company that is continuing to manufacture the energy devices that it supplies to buildings including supermarkets and hospitals, now has production lines bringing old ventilators back into service. Two weeks ago, as coronavirus cases surged in the U.S., the governor of California put out a call for manufacturers to help fill critical gaps in equipment, including ventilators. KR Sridhar, Bloom’s CEO, responded. “If you take it down to a lower level, and you look at kind of what are the base technologies that support a ventilator and the base technologies that support a fuel cell, it’s batteries, pumps, valves, airflow—and that’s what we do,” says Susan Brennan, Bloom’s chief operating officer. “So he immediately reached out to the governor and said, you know, we can help here.”

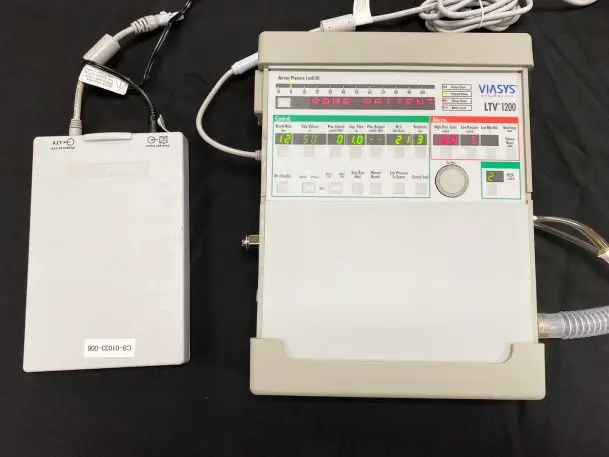

A few days later, Bloom received a small shipment of 24 ventilators that hadn’t been used since the H5N1 bird flu outbreak more than a decade ago. The day before they arrived, the team got ready. “An engineer who works out here in California downloaded the manual for the ventilator that we would be refurbishing and taught himself how to build and repair ventilators overnight,” says Brennan. “So when he came into work Thursday morning, he had a process flow and process sheets ready to go.”

The engineer spent the day on Zoom along with coworkers in the company’s Delaware office. The ventilators arrived that Friday, and by Saturday, the team had refurbished all of them, making tweaks like charging or changing batteries, checking sensors, and sometimes replacing other parts. (The changes are relatively straightforward; Bloom says that it rejects ventilators that need more complicated repairs.) By contrast, when California’s governor talked to the original manufacturer about refurbishing a set of 200 ventilators, he was told that it would take a month.

The company partnered with Stanford’s pulmonary lab to test the equipment, along with a company called Cure Biomedics that services hospital equipment. “They set up all the proper oxygen calibration equipment and trained our employees,” Brennan says. Bloom added new manufacturing lines to its California and Delaware facilities and began to work. So far, it’s received 550 old ventilators and shipped more than 350 refurbished units to the State of California, which will distribute them to hospitals. More will soon be delivered on the East Coast. Anyone with stockpiles of ventilators in need of repair can contact the company. “As long as we have supply coming in, we are continuing to refurbish and ship out as fast as we can,” she says.

The need is obvious. One hospital in New York City has reportedly already come close to running out of ventilators; the head of hospitals in the city said last week that there were only enough ventilators to last through the end of March. In Italy, which may serve as a preview of what will happen in the U.S., some doctors have been forced to choose who will get access to the equipment and who will die. While other efforts will be needed, including the work that other companies are undertaking to make new ventilators, refurbishing has the advantage of happening more quickly. Bloom expects to be able to refurbish around 1,000 ventilators a week.

It’s also happening near hospitals that are in dire need—the California factory can serve the growing cases in California, and the Delaware factory can serve the surge in New York, making deliveries within hours. “This is a really good reminder and representation of the power of American manufacturing, and Americans coming together to support the community—and why these are critical skills that we want to keep in the U.S.,” Brennan says.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.