Every year, Adidas makes more than 400 million pairs of sneakers. These shoes are part of the 900 million items–including clothing and sports equipment–the 70-year-old German conglomerate puts out into the world annually. Adidas’s mission is to create high-performance products for athletes, so the vast majority of the materials it creates are made from plastic polymers, which have the remarkable ability to be transformed into everything from springy foam in sneakers to moisture-wicking fabric in sports bras.

The problem with plastic is that it does not biodegrade. Since plastic in shoes and clothes are not currently recyclable, it ends up in landfills–or worse–the ocean, where it adds to all the plastic ever created. Adidas is not the only culprit: According to the Ellen MacArthur Foundation, 60% of all materials used by the fashion industry are made from plastic, which, in turn, comes from oil, a non-renewable resource. Adidas recognizes that it is a major contributor to the plastic pollution problem, and today, it is laying out a comprehensive plan of attack to end plastic waste in its products within the next decade. This will involve using recycled materials and designing fully recyclable products in the short term. Longer term, the company’s goal is to switch to biodegradable materials. But this is a far more difficult project–one that depends on what technologies emerge in the years to come–so Adidas is not putting a time frame on this.

“We know that plastic makes up the largest part of the materials we use,” says James Carnes, vice president of brand strategy at Adidas. “And we know that there’s no such thing as throwing plastic ‘away’; in the best case scenario, it is responsibly managed in a landfill, and in the worst case scenario it ends up on beaches in a coastal town. So we’ve come up with strategies to take responsibility for the plastic we’re introducing into the world.” The strategies include everything from redesigning its products to ensure they can be recycled easily to scaling up its use of plastic recovered from old water bottles and ocean waste.

A Goal Five Years In The Making

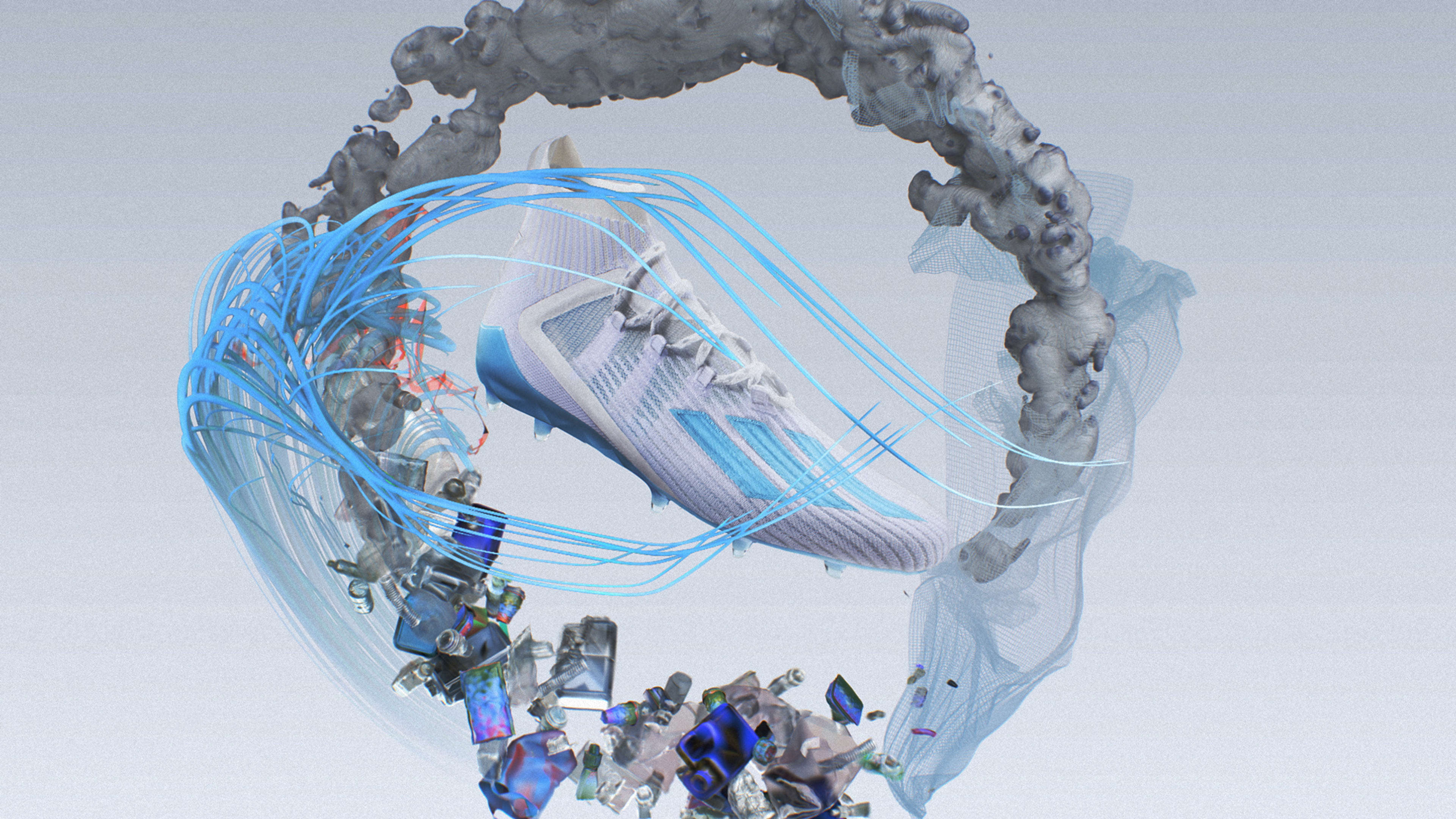

Adidas began developing its current sustainability strategy in 2015, when it conducted an audit around the materials it used. Since then, it has experimented with different solutions. In 2015, Adidas collaborated with the environmental organization Parley for the Oceans to make clothes and shoes using plastic fished out of the ocean. Adidas launched with 7,000 pairs of sneakers, but then scaled up to 11 million sneakers the following year. Last year, my colleague Mark Wilson wrote about Adidas’ efforts to create a fully recyclable sneaker, an endeavor that is much harder than you might imagine. The shoe, dubbed the Futurecraft Loop, was made out of a single material and welded together with heat, no glue needed, so it can be easily shredded and turned into new material that can go into a new shoe. “The number one contaminant in plastic recycling is glue,” says Carnes. “So we had to fuse the plastic together. But here’s were plastic is an amazing material: It can be engineered to exist within a circular system.”

Until now, these projects were experimental. Through its in-house design lab, called the Speedfactory, Adidas can quickly turn ideas into prototypes, then into small-scale, limited-run product launches. This process involves quickly finding suppliers and technology partners that can do everything from supply ocean plastic to shred plastic shoes. But Carnes says that the company is now ready to overhaul its entire plastic manufacturing process to make it much more sustainable. “2020 is all about scaling up,” he says.

Step 1: Use Recycled Plastic At Scale By 2024

The first step, will be transitioning the company to recycled plastic. By the end of this year, half of all polyester will be from recycled sources, and by 2024, all polyester that the company uses will be recycled. The company plans to introduce labels that explain exactly where the polyester comes from. Products labeled PrimeGreen will use polyester derived from recycled water bottles, while products labeled PrimeBlue will be ocean plastic provided by Parley. Since this will require much more plastic than Parley currently intercept plastic from remote islands, beaches, coastal communities and shorelines, Adidas will collaborate with Parley to extract plastic from beaches around the world.

Of course, polyester is just one of the plastic materials that Adidas uses in clothes and shoes. Carnes says Adidas is also working to find recycled polymers for plastic in other products, such as the foam in shoes. This is a longer process, partly because there hasn’t been as much industry demand for recycled PVC and PU foams. Over the last couple of years, as fashion labels ranging from Everlane to swimwear brand Summersalt have switched to recycled plastics, there has been an increased demand for recycled polyester, which means that manufacturers have been working hard to produce the material and improve its quality. But that hasn’t happened for other forms of plastic. “We’re trying to create the demand ourselves, and we’re working with partners to help find these materials,” he says. “We can’t say that we’re working to end plastic waste unless we think about all plastic in our supply chain. I can confidently say than in the next 10 years, we’ll have the technology to do so.”

Step 2: Make Recycling Easy By 2030

Recycled plastic is just one part of the process. The next step is creating products that can be easily recycled so there is an entirely circular system at work. As the Loop example demonstrates, this will involve redesigning products from scratch so they are either made from a single material or from materials that can be easily separated and recycled separately.

Of course, it’s not enough to create shoes consumers can recycle: Adidas also has to figure out some way of making sure the shoes are recycled. The company is tinkering with the idea of sending return labels and temporary shoes to customers, until they send back their old pair, in addition to other approaches. But as Mark Wilson points out in his story, it might take more to convince customers to part with their shoes, particularly if they’re attached to them.

Step 3: Make Products Biodegradable By…

The final step in Adidas’s plan is to create products that are entirely biodegradable. Unlike the other two steps mentioned above, this one does not have a fixed timeline. “This is the holy grail,” Carnes says. “We want to create a circular system, but this depends on consumers recycling the products. If we make product that will return back to the earth, it takes the responsibility off them to close the loop.”

Adidas continues to be a major cause of plastic pollution, but it deserves credit for acknowledging the extent of its responsibility and coming up with a strategy for ending plastic waste. And by investing in and scaling up sustainable technologies–like recycled plastic foam, or bio-based materials for shoes–Adidas will pave the way for other brands to access more sustainable materials as well. “As a big company, Adidas has been a big contributor to the problem,” reads a statement the brand put out today. “Which is why its actions need to be equally as big.”

We couldn’t agree more.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.