Fashion’s trash problem is partly a planning problem: When brands try to project demand for a particular shirt or dress, they often end up making far too many clothes. Last March, H&M reported that it had $4.3 billion in unsold inventory. In July, Burberry admitted that it had destroyed $36.8 million worth of its own unsold clothes; facing outrage, it later announced that it would stop the practice, though other brands routinely do the same thing. By one estimate, 30% of the 150 billion garments produced each year are never sold.

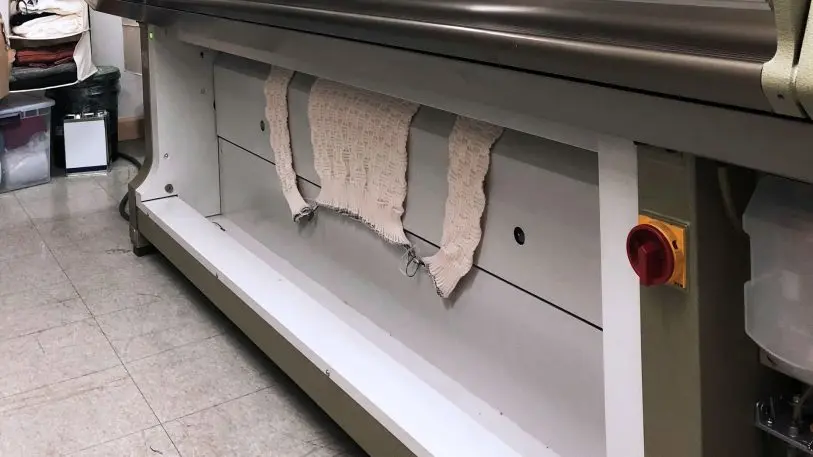

[Image: Tailored Industries]To combat this waste, some startups are trying to convert the industry to an on-demand model. Tailored Industry, a knitwear manufacturing startup based at the Brooklyn Army Terminal in New York City, uses software to connect brands to its 3D knitting machines. At its facility, the company uses Japanese-made knitting machines that can knit the sleeves and body of a sweater simultaneously without any cutting and sewing–another step that reduces waste compared to some other methods of production. The startup still makes larger production runs. But they’re trying to convert more brands to the new approach. (Making clothing on demand costs slightly more per piece than a run of hundreds of items, but companies can save later, in theory, because they don’t have extra costs of warehousing and marking down unsold garments.)

This could mean that if a customer places an order in an online store, it’s routed to the factory to be made right then. For brands with physical stores, the company can produce a small amount of stock, and then monitor sales to produce more as needed. Companies aren’t forced to mark down goods on clearance, or throw out or destroy clothing that took resources to make–and that already contributed to the industry’s growing carbon footprint.

Some brands have been slow to consider the shift, the founders say, though others, like Steven Alan, have already worked with the company, and the startup says that its current small facility already has more demand than it can handle. It’s also in talks with larger brands about pilot tests. With its next round of seed funding, the company plans to scale up the factory it has in Brooklyn, and it envisions creating a network of local production facilities that make clothing on demand for local markets. “The idea is to really have the products made where they’re going to be locally consumed,” says Tschopp.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.