Swiss engineers have developed a construction technique that could change how buildings are designed and built. It’s called a “Smart Slab:” A mixture of concrete, rebar, and carbon fiber that form a super-light, super-strong slab ceiling. It’s an entirely new way of building structural elements, and even at less than an inch thick and less than half the weight of a conventional concrete slab, its creators at the Digital Building Technologies group at ETH Zürich claim it can support more weight–surpassing Swiss building code standards.

Inspired by gothic architecture, researchers at ETH–a science, technology, engineering, and mathematics university in Zürich, Switzerland–used CAD software to design the slab, calculating its optimal three-dimensional shape to effectively distribute the weight it needed to support. That process meant the final design was exactly as thick as necessary and no thicker, saving material and weight but keeping maintaining strength and stability. “We didn’t draw the slab,” says Smart Slab project lead, Mania Aghaei Meibodi, on the project page. “We programmed it.”

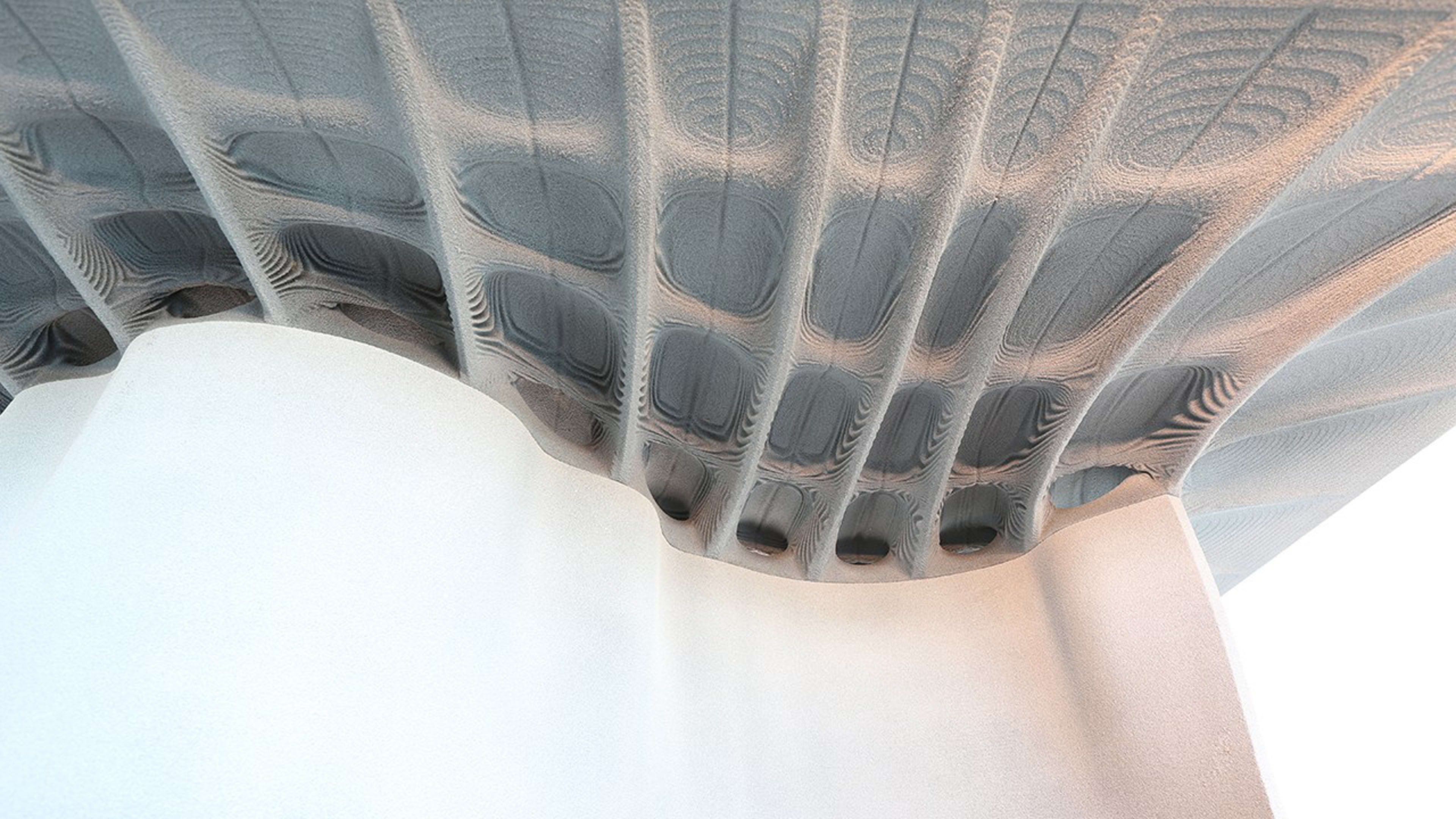

To actually build the optimized design inside the DFAB House, a fully functional building that serves as a testing ground for advanced digital construction technologies, the team Smart Slabs had to concoct a way to fabricate the complex shape. Using a large-scale 3D printer that mixes sand and binding polymers, they manufactured molds precise enough to be used to cast the slab. They also laser-cut timber forms to create the ribs that hold the slabs together.

Finally, when both molds were ready, they filled them with a spray-on mixture of concrete and carbon fiber. In total, the EHT engineers installed eleven high-performance concrete and carbon fiber slabs to form the 861-square-foot, 15-tonne ceiling that connects the lower floor of the DFAB house with a two-story timber structure that sits on top. The workers, the engineers say, only needed to add steel cables to put it all together, which were tensed to “massively [increase] the system’s load capacity.” And since it was all fabricated with such precision, the group says the assembly process was very fast, although they didn’t disclose how much faster the process is compared to traditional concrete casting done at a typical construction site.

The DFAB house is becoming quite the showcase for wonderfully innovative construction technology. Earlier this year, I wrote about how the group is experimenting with complex wood structures that can be assembled by robots.

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.