In a 72,900-square-foot former pharmaceutical facility in Nutley, New Jersey, test tubes sit atop lab tables crowded with microscopes and trays of materials. Out in the main area, huge fermentation vats churn.

This is not what you would imagine when you think of a leather production facility. Leather is one of the oldest materials in the world, created by killing an animal, stripping its skin of hair and fat, and treating the leftover materials with oils and chemicals (or way back in the day, urine and lime). Ancient Egyptians made leather sandals; cowboys rode on leather saddles. If any material seems outside the reach of innovation, it’s leather.

Related Video: It Looks, Smells, And Feels Like Real Leather–But It’s Grown In A Lab

Modern Meadow’s sustainable alternative to leather is the latest innovation in the field of cellular agriculture, the process being used by companies like Impossible Foods and New Wave Foods, which are applying food science and genetic engineering to develop eerily accurate plant-based meats. The startup is revealing its product for the first time at an exhibit focusing on the future of fashion at the Museum of Modern Art in New York this fall. The company has designed a T-shirt created with its liquid biofabricated leather, called Zoa, to showcase the materials’ properties and various uses.

That, says Susan Schofer, Modern Meadow’s VP of business development, got him thinking about skin cells, and leather in particular. Modern Meadow’s first forays into leather substitutes involved growing the material from actual cow skin cells–a process not unlike that used by the Netherlands-based company Mosa Meat, which is developing “cultured meat” products in a lab using animal stem cells. Indeed, in the early days of Modern Meadow, the team was looking to develop meat alternatives as well, but decided to zero in on biofabricated leather, as the concept was, compared to meat alternatives, relatively unexplored.

And there is a huge need to do so: Despite its long history of use as a clothing material, leather sits at the intersection of some of the most wasteful and polluting activities on the planet. It’s derived from livestock–mostly cows, pigs, goats, and sheep–the mass raising for which meat and materials production accounts for more than half of global greenhouse gas emissions. And while leather has uses beyond fashion and accessories, it’s a staple in that industry, which comes second only to oil as the world’s most polluting sector.

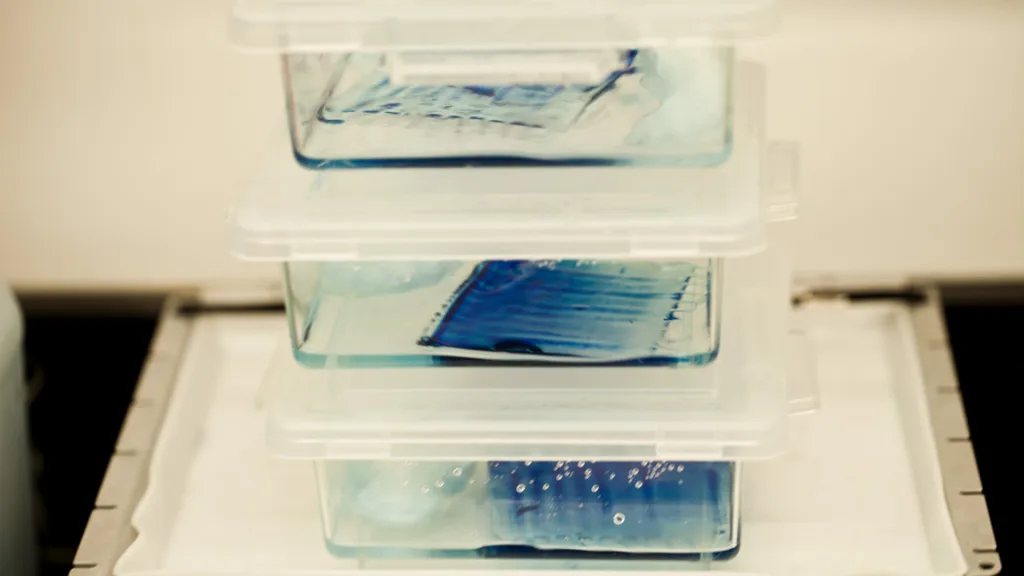

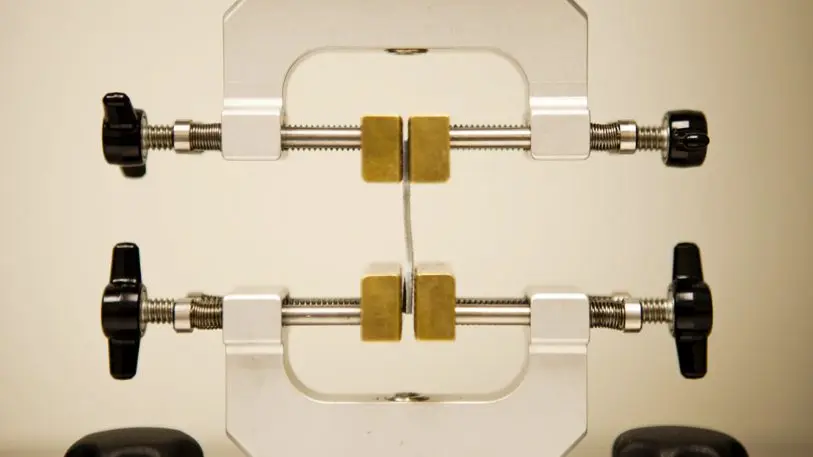

Getting to this point, though, was a process of trial and error. Modern Meadow’s initial process of growing leather from animal cells is called tissue engineering, says Suzanne Lee, the chief creative officer, and it involves raising the cells in a material composed, in part, of a serum extracted from unborn calves. The process is very particular and precarious–if bacteria infiltrate the cell growth process, the whole operation could derail, and the equipment needed to protect against that event is very expensive. Furthermore, there’s no real supply chain in place to source either the animal cells or the serum needed to grow them in, so acquiring them at scale would be prohibitively expensive, Lee adds. And the fact that the material is, fundamentally, animal-derived negates the possibility of claiming the label “vegan” or “animal free.”

So in 2014, Modern Meadow switched its manufacturing process. Instead of using animal cells, the company began growing collagen–which is essentially what is left over after the hair, fat, and tissues are removed from skin–from yeast. “It’s a brand-new technology that enables us to grow the building blocks of nature, using a cell that we design and engineer ourselves,” Lee says. “In this instance, that cell is collagen, the protein that you find in your skin and in animal skin, and that really is the fundamental material that composes leather.”

The process, Schofer adds, is highly scalable. “No one has ever engineered a yeast cell to produce collagen in the quantity that we need it to,” Lee says. That ability has allowed Modern Meadow to drive down its production costs to the point where their materials are on par with the cost of traditional leather. The yeast is fermented in large vats, like those used to make beer and wine, and the resulting liquid collagen is both large in quantity, and highly adaptable to various uses.

Because Modern Meadow’s product and animal-derived leather have, essentially, the same chemical structure, they react in much the same way to external forces. Like animal leather, Modern Meadow’s product is also biodegradable, but can be tanned and treated for more durability, Lee says. That tanning process, too, is what gives animal leather its distinctive smell, so Modern Meadow duplicates that, as well. Though the MoMA shirt is just black leather, the biofabricated material can be also be dyed.

The Modern Meadow team is able to create not just a uniform sheet of leather (though it can certainly do that), but a whole variety of materials. There’s a paper-thin leather that can be poured onto fabric as a T-shirt applique; there’s a thick, pebbled hide that could form a handbag. Zoa, the liquid leather modeled in the T-shirt at the MoMA, can act almost like paint–the material can be drizzled into almost Jackson Pollock-like patterns. It can also act as an adhesive. The MoMA shirt is a patchwork of mesh and cotton, joined together by the liquid leather, which merges seamlessly with the other materials.

The possibilities of the new material has the design and fashion world very excited. Modern Meadow has been approached by around 150 companies from a variety of sectors: fashion, sport, automotive, and interiors. The company won’t disclose the names of their partners, but it says that around two will be bringing products developed with Modern Meadow to market next year.

While interest in Modern Meadow has been strong, the process of explaining to companies and designers how, exactly, the material works has been a bit of a challenge, Schofer says. “Fashion, and any sector that uses textiles or traditional leather, are not really used to the timelines of biotech R&D,” Schofer says. Modern Meadow explains to companies that what they’re offering them is not a raw material, but an opportunity to work together to develop a product that will integrate specifically with a design. So for example, if a brand wants to develop a T-shirt with biofabricated leather decals, Modern Meadow will not just present them with a sheet of leather that they can then cut up and applique; instead, they’ll work with the designer to mold the leather to the design, adjusting the flexibility and weight accordingly, and the material will adhere seamlessly to the fabric.

Schofer and Lee believe that the advantages of working with Modern Meadow will outweigh the potential difficulties. Using Modern Meadow’s materials will not necessarily be more expensive–sourcing animal products is very expensive. And especially for luxury designers, who are in the business of trying to push the boundaries of innovation in the industry, working with Modern Meadow to develop unique applications of leather–in all its different, biofabricated forms–holds a lot of appeal, as does the material’s light environmental footprint. But still, questions remain: As Modern Meadow grows, will it be able to remain committed to tailoring its leather for exact uses? Or will it have to default to mass-producing in order to meet demand? And if so, will it be able to ensure that its material does not go to waste?

These questions, though, are still far in the distance; Modern Meadow has a ways to go before it hits the mass market. Still, though, the company is gearing up for massive growth–it’s already expanded from around 10 people in 12,000 square feet of lab space when Schofer started, to around 70 people in a 72,900-square-foot space, and backing from the likes of Horizons Ventures and Tony Fadell.

“We’re really focused on the long-term,” Schofer says. Just like how Modern Meadow’s collaboration with designers and other industries is not a one-and-done exchange, but rather a long, collaborative process, so the company will continue to iterate its product. “It’ll be multigenerational work to constantly improve the strain of the yeast and work on creating an organism that will produce as much collagen as we can get it to,” Lee says. “That’s ongoing, and it’ll probably be ongoing for the life of the company.”

Recognize your brand’s excellence by applying to this year’s Brands That Matter Awards before the early-rate deadline, May 3.