How often have you gone to a grocery store, picked out what seems to be a fresh pint of blueberries, and opened the refrigerator door the next day to find half of them covered in mold? If your answer is “all the time,” you’re not alone: Those best-by dates that give us such blind confidence in the shelf life of our produce are nothing more than “a soft assurance,” says Peter Mehring, CEO of Zest Labs, a Silicon Valley-based tech company dedicated to preserving produce and grocery product quality along the supply chain. And in addition to frustrating customers, inaccurate sell-by dates result $30 billion of wasted food in the U.S. each year.

Through its new Zest Fresh tool, which was rolled out last fall and is now delivering measurable results, Zest Labs is helping food retailers better identify best-by dates to reduce the food wasted in transit or tossed after rotting unsuspected in fridges. Zest Fresh, Mehring tells Fast Company, uses real-time, sensor-based tracking to consistently monitor the freshness of a product, from time of harvest to when it hits retail shelves. Given that in the U.S. around $165 billion worth of food, or 40% of the total produced, is thrown out into landfills each year–with losses related to inconsistent freshness and sell-by dates accounting for 33% of that–Mehring and the team at Zest Labs saw an opportunity to use tech to cut back on some of that waste.

For retailers and farmers, implementing Zest Fresh technology is simple: All that’s required is installing sensors, which detect temperature, moisture, and location, on the produce pallets assembled in the fields before distribution, and connecting the sensors to the Zest Fresh cloud, which disseminates data to the various players along the supply chain. Most retailers, when they source produce from growers, expect it to arrive from the distribution center with 10 days of freshness remaining. In a series of baseline studies conducted at retailers throughout the country, Mehring found that only 30% of products actually arrived with that target freshness. After installing Zest Fresh technology in the pallets of farmers they source from, the number of products that arrived with 10 days of freshness to spare jumped to over 90%.

Say you’re a lettuce farmer, and you’re working on getting a harvest to the distribution center. “The problem is, there’s an assumption that all produce harvested on the same day will have the same shelf life,” Mehring says. “That’s historically how sell-by dates are determined.” But in reality, a pallet of lettuce assembled in the early morning and sent immediately to the cooling center will already have a longer shelf life than a round from the same crop that was cut and assembled later in the day and left out in the hot sun for a while before making it into a refrigerator.

Related link: The Companies Trying To Track Everything We Eat, From Seed To Stomach

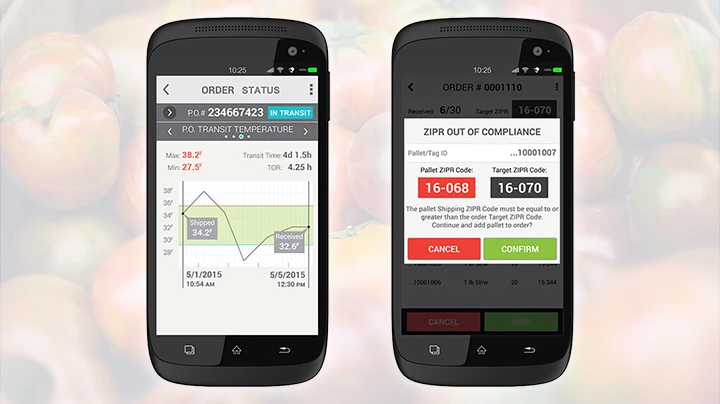

For each product, Zest Fresh provides a target ZIPR code that a pallet must hit in order to proceed along the supply chain (the ZIPR code is derived from the data sets tracked through the Zest Fresh cloud, and reflects both the product type and its temperature and exposure to humidity over time). Based on where a pallet’s ZIPR code falls in relation to the target code, Zest Fresh offers an estimate for the days of freshness remaining for each pallet. That estimate is dynamically updated along the supply chain; any time a product is mishandled–say, left out of a cooling facility for too long–the remaining freshness estimate will reflect that. “That allows someone in the distribution center to make an intelligent decision and say, ‘Okay, I expected 10 days of freshness, but this product only has 8 days left–I better send it to the store this afternoon instead of tomorrow,'” Mehring says. “We’re giving people actionable data to take corrective steps.”

When it comes to reducing supply-chain and retail food waste in the industry, this data-driven approach, Mehring hopes, will be a game changer. Clarifying and backing up best-by dates could be a significant factor in reducing unnecessary food waste: A report from the nonprofit ReFED found that standardizing food freshness labels could divert as 400,000 tons of food waste annually, and save $4,547 per ton. Doing so, the report added, would also curb emissions by cutting back on unnecessary transit of products that end up in landfill, and save as much as 192 billion gallons of water.

Recognize your company's culture of innovation by applying to this year's Best Workplaces for Innovators Awards before the extended deadline, April 12.